Metron’s titanium additively manufactured handlebars boost cycle performance

February 24, 2020

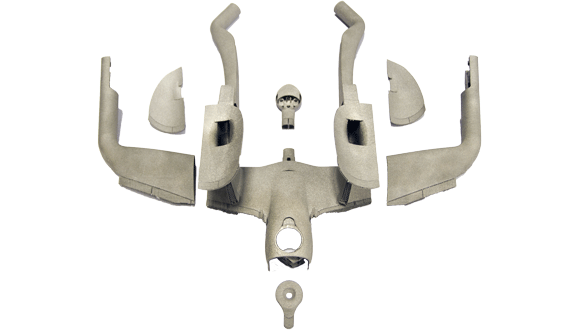

Metron Additive Engineering, based in Ilkeston, Derbyshire, UK, has now produced over one-hundred additively manufactured titanium handle bars for high performance cycles using GE Additive Arcam Electron Beam Melting (EBM) technology. To date, the company has seen bikes using its handlebars win a combined total of eighty-seven world championship and Olympic gold medals.

Metron Additive Engineering was founded by Dimitris Katsanis, a former elite cyclist, who has been at the forefront of the design and manufacture of Olympic, Tour de France and world championship bicycles for over thirty years. The company began producing its titanium EBM handlebars in 2015, when approached by Sir Bradley Wiggins during preparation for the Hour Record – the longest distance cycled in one hour from a stationary start.

“The bike was made from carbon fibre, but the handlebars were titanium, created using a GE Additive Arcam EBM machine. This meant that we were could intricately modify them multiple times leading up the record attempt,” recalled Katsanis. A replica of the handlebars is on display at the V&A Museum in London.

Carbon fibre, as well as aluminium, have long been the material of choice for professional cyclists because of their light weight and strength. Now, industry focus is turning towards titanium and parts produced using Additive Manufacturing.

Katsanis was surprised when the first additively manufactured titanium bicycle parts built were lighter than the equivalent parts in carbon. “The first few that we made were very integrated designs and we were getting rid of a lot of nuts and bolts. I realised that with 3D printing in titanium, it’s possible to put the material where you need it and remove it from the areas you don’t.”

“Additive technology allows you to do things that you otherwise couldn’t. It’s partly design and partly engineering. Additive has allowed me to take 25 years of composite engineering experience and make more dynamic, organic shapes with more complex designs,” he explained.

Despite this, Additive Manufacturing is still some way from becoming the default technology for consumer bikes, something that Katsanis is looking to change. Metron is negotiating with well-known bike manufacturers to provide AM titanium parts at scale, using GE Additive Arcam EBM technology.

“The EBM process allows us to stack components one on top of the other with the ability to make a lot of components in one build. So, in general, we can make components lighter, but the specific benefit of EBM is its efficiency, meaning our products are more price competitive,” he stated.

Beyond the cycling industry, both in high end and more mainstream applications, Metron plans to expand its Additive Manufacturing expertise and experience into medical technology and aerospace. Katsanis sees a rapidly expanding future for AM, first in high end products and then with mass penetration as AM technology reaches ‘critical mass’.

“I think mass customisation of additive titanium parts will be the next big step. I think in the next two-to-three years, 3D printing will grow in the high-end and specialised product market, but within a decade we’ll see Additive Manufacturing start to filter down to more medium range and, possibly, everyday products.”

“I would really like to see additive technologies evolve and trickle down to everyday products,” he continued. “By showing that we can mass customise tens of thousands of bike parts annually, we are demonstrating that it is possible to produce components in large quantities with additive technology. We are determined to be a pioneer in showing that Additive Manufacturing can be brought to scale.”