Metal additively manufactured bone drill with integrated cooling channels improves surgical processes

July 10, 2017

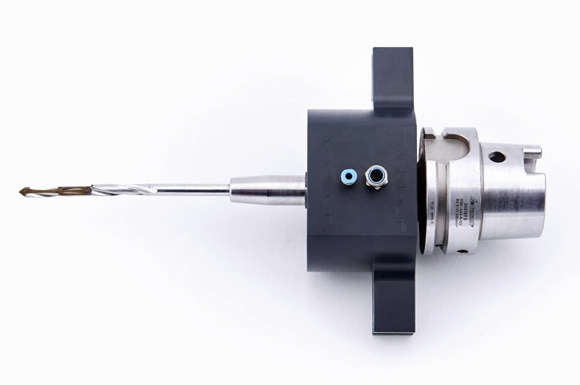

The internally cooled bone drill (Courtesy toolcraft)

In collaboration with toolcraft, Germany, The Institute of Production Engineering and Machine Tools (IFW) at Leibniz University, Hannover, Germany, has produced a new bone drill using metal Additive Manufacturing. The new drill is designed to address the problem of thermal-induced osteonecrosis in traditional bone drilling surgeries.

Thermal-induced osteonecrosis is caused by the heat produced when cutting bone using traditional bone drills. Osteonecrosis develops when blood flow is restricted to the bones in the joints. With too little blood, the bone starts to die and may break down. Cooling conventional tools during use runs the risk of fluid entering the wound, which can negatively impact patient outcomes. As a result, bone surgery is currently performed iteratively, with the drilling process being repeatedly interrupted in order to cool the tool and keep the temperature as low as possible.

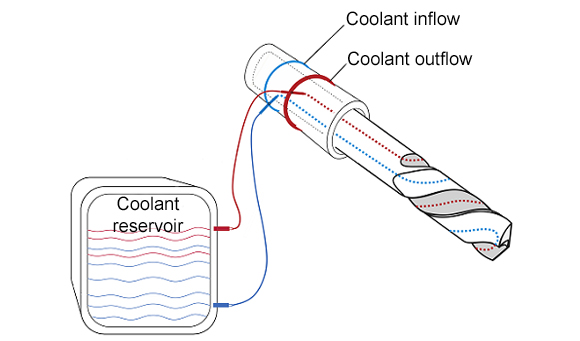

Using metal AM, toolcraft and IFW have manufactured a bone drill with integrated cooling ducts. This allows coolant to flow inside the tool, along the helix of the drill and back to the tool holder, without the risk of fluid entering the wound. toolcraft also developed a non-rotating pre-spindle attachment with an inflow and outflow function for the coolant, a continuous supply of which is guaranteed by an attached coolant tank and pump.

Developing a new solution

Consistent cooling system inside the bone drill (Courtesy toolcraft)

The prototype for the new bone drill was modelled on a conventional bone drill with a 6mm diameter bit. According to IFW, it was important to keep the design as close to a conventional bone drill as possible so that surgeons would not be required to undergo extensive retraining to use it.

At the outset of the project, the required cooling capacity was determined in terms of the volumetric flow rate, temperature and thermal capacity of the coolant. toolcraft’s project team then developed a method for bringing a closed cooling circuit into the tool substrate while maintaining tool stability, and ensuring that the tool was suitable for performing the required processes and highly compatible with patients.

The shape of the drill and its internal cooling ducts were designed by Schmidt WFT using CAD and simulation software. The drill was then additively manufactured from biocompatible material 1.4404 and machined to its final size. Following manufacture, it underwent extensive practical tests at IFW; using water as a coolant, the university team tested the drill on both artificial and bovine bone while measuring the process temperature.

The results of the drilling tests showed a significant temperature reduction of around 70%. This is a key development for bone surgery of all kinds; all forms of bone cutting and sawing carry a risk of thermal-induced osteonecrosis. Following the successful development of toolcraft’s internally cooled bone drill, the technology could also be used to develop a range of bone saws and other surgical implements.