Meltio Space toolpath generator software launched for robotic Additive Manufacturing

August 30, 2023

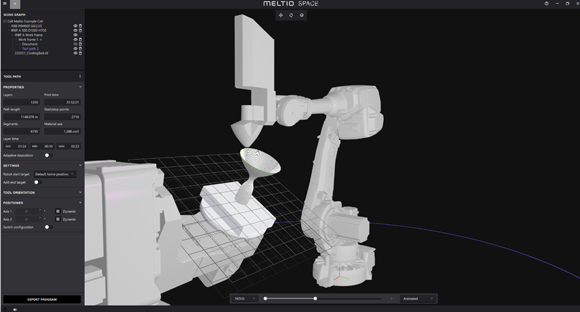

Meltio, based in Linares, Spain, has unveiled its Meltio Space software, aimed at increasing the reliability of metal part manufacturing by producing accurate parts. Meltio Space is a toolpath generator software that integrates with the Meltio Engine Robot, and is said to feature an easy-to-use interface for creating planar, non-planar, and variable extrusion toolpaths. Additionally, it includes 2-axis workpiece positioner interpolation, kinematics simulation, collision checking, and cell configuration.

The toolpath generator software was developed specifically for accelerating the adoption of Meltio technology, allowing users to quickly adapt to and leverage the benefits of robotic AM without requiring expertise in robotics or programming.

By integrating a 6-axis robotic manipulator and 2-axis workpiece positioners, it is said to open up a new realm of possibilities for metal Additive Manufacturing. With comprehensive coordination, multi-axis toolpath generation, and enhanced design freedom, Meltio Space enables users create intricate, customised, and highly detailed metal parts.

Before its launch, the company had signed agreements with 12 major software companies.

“Meltio Space makes it possible to design very reliable parts as quickly as possible and with a wider range of possibilities for our industrial customers. And this is thanks to a very user-friendly interface of the Meltio Engine Robot Integration. Meltio Space also includes preset and recommended material profiles and 3D printing parameters and a series of specific processors for robot arms from ABB, Kuka, Fanuc, and Yaskawa including collision detection, and simulation. Industrial applications are improved thanks to the new Meltio Space software in which the learning curve of our Engine integrators was very low because they depended on third-party software and those developers do not have the knowledge that we can have in Meltio of the Meltio Engine,” stated Meltio Engine Product Manager, Alejandro Nieto.

“So the main goal of our technology is to give the most efficient tool that allows the industry the most of the applications they need to manufacture metal parts with our wire-laser technology. Meltio Space is a living platform that will provide feedback to keep improving and offers competitive software to different industrial customers of Meltio.”

Meltio Space robot slicer utilises a virtual model of the actual robot’s movement. This advanced feature enables users to simulate the robot’s kinematics, ensuring accurate and precise construction. Furthermore, the slicer performs collision checks with the part being printed, minimising the risk of errors or damage during the Additive Manufacturing process.

Download Metal AM magazine