MELD researches recycling of battlefield scrap metal for on-demand repair and manufacturing

August 14, 2018

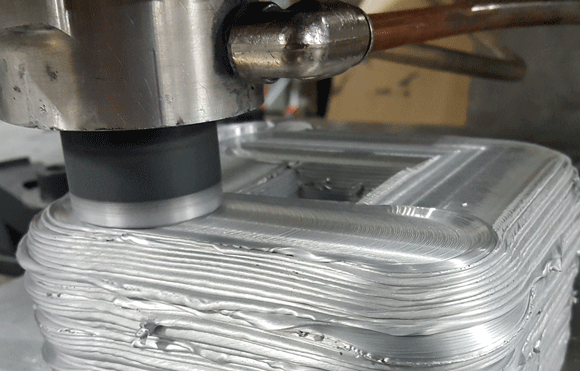

MELD is a solid-state process which can use a wide range of materials as feedstock, including metal powders and rods (Courtesy MELD Manufacturing)

MELD™ Manufacturing Corporation, the University of Alabama and the U.S. Army Research Lab (ARL) have been awarded funding by the USA’s Strategic Environmental Research and Development Program (SERDP) to support basic research into the implementation of MELD’s metal Additive Manufacturing technology as a method for recycling battlefield scrap metal for repairs and manufacturing in combat theater.

The research was proposed in response to the Army’s published search for methods of manufacturing at the point of need. Throughout the project, MELD will create samples from scrap provided by ARL before sending them to both the University of Alabama and ARL for analysis.

“The capacity to take battlefield scrap and use it at a forward operating base for repairs and other manufacturing processes would be a significant time and cost-saving ability,” stated Nanci Hardwick, MELD CEO. “MELD machines are uniquely capable in this area as they can deposit from multiple types of feedstock and require no special chambers or vacuums for operation.”

MELD announced earlier this month that it was selected for Phase I of the US Army’s xTechSearch for its proposal to create strong, lightweight materials for combat vehicles. The company clarified that while both projects will explore military applications for the company’s technology, the SERDP project will research the fundamental characteristics of MELD deposits using feedstock created from scrap, while the xTechSearch-funded project is a demonstration of field-usable equipment to take a waste stream or indigenous materials as raw MELD material.

“It’s exciting to be taking part in both the XTechSearch and this SERDP project,” added Hardwick. “We’re proud of our technology and are eager to continue showing the world more ways that MELD can save time and money while reducing environmental impact.”