MELD metal Additive Manufacturing machine installed at University of North Texas

September 10, 2020

The University of North Texas (UNT), based in Denton, Texas, USA, has installed a metal Additive Manufacturing machine from MELD Manufacturing Corporation, Christiansburg, Virginia, USA. The B8 model MELD® machine is expected to allow researchers to explore a variety of materials and use cases for metal AM.

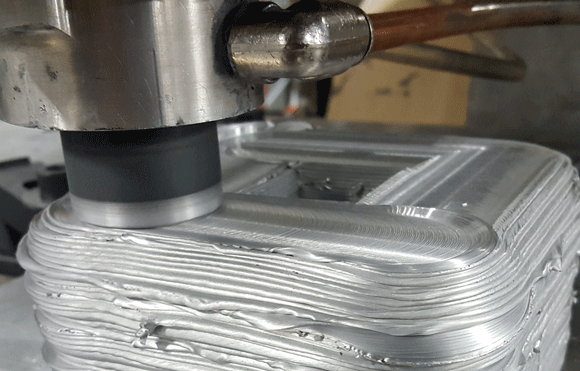

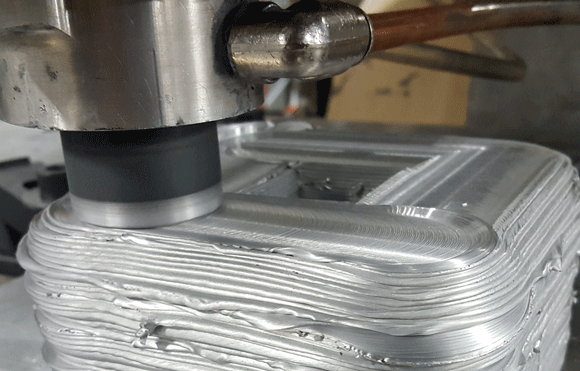

MELD is a patented Additive Manufacturing process based on a process similar to friction welding, and can be used for the building and repair of metal components using off-the-shelf solid-state materials or powders. The process does not involve melting and is capable of Additive Manufacturing fully dense parts.

While many metal AM processes require specially-formulated materials, MELD’s technology allows the use of existing alloys in materials such as aluminium, magnesium, and titanium.

The B8 model has a three cubic foot 305 x 305 x 914 mm (12 x 12 x 36 in) build area and can accommodate large parts for coatings and repairs. The machine can process multiple materials and has been designed for industry and academia alike. It was recently used in a demonstration to make what is said to be the world’s largest additively manufactured aluminium cylinder.

The university’s research activities using the MELD process will be overseen by Dr Rajiv Mishra, Distinguished Research Professor of Materials Science and Engineering, an expert in the development of alloy microstructures and the processing of material properties.

Dr Mishra serves as Director of the Advanced Materials and Manufacturing Processes Institute, as Director of the NSF Industry/University Cooperative Research Center for Friction Stir Processing and as Associate Editor at the Journal of Materials Processing Technology.

The MELD machine is housed in a dedicated space located in the College of Engineering’s new Discovery Park facility. With nearly 300 acres of space dedicated to the sciences, technology and engineering, Discovery Park supports interactive and multidisciplinary STEM (Science, Technology, Engineering, and Mathematics) research, education, and training that benefits students, faculty, and the community.