MELD Additive Manufacturing technology to support combat vehicle development

August 1, 2018

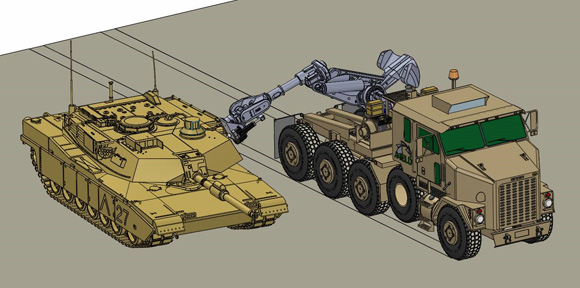

Conceptual image of a combat vehicle repair using MELD (Courtesy Meld Manufacturing Corporation)

MELD™ Manufacturing Corporation, Christiansburg, Virginia, USA, states that its patented MELD metal Additive Manufacturing technology has been selected by the US Army to be part of its inaugural Army Expeditionary Technology Search (xTechSearch). The xTechSearch reportedly aims to identify potential collaborators which can work with the army to address the challenges of modernisation.

MELD has been selected for Phase I of the programme based on its proposed use to create lighter-weight, higher-strength materials for the US Army’s next generation of combat vehicles. Dr Chase Cox, Meld Additive Manufacturing Manager, explained, “The MELD technology is ideal for combat vehicles because it enables the use of unweldable metals and can create, join, coat, or repair a wide range of novel metallic materials that offer superior strength and corrosion resistance without adding weight.”

“Additionally, MELD machines do not require a laboratory environment for operation and are highly scalable,” he continued, “making them perfect for implementation on the battlefield. Being able to repair parts or manufacture components on demand in theatre would both elevate efficiency and save time and money.”

MELD Manufacturing Corporation holds more than a dozen patents for its MELD technology, which makes it possible to build components in solid state, thereby avoiding the issues associated with melting. The technology is also open-atmosphere, meaning no special vacuums or chambers are needed for operation.