Mazak MegaStir named exclusive tooling supplier for MELD technology

June 8, 2023

Mazak MegaStir, Florence, Kentucky, USA, has signed an agreement which makes it the exclusive supplier for solid deposition technology from MELD Manufacturing, Christiansburg, Virginia. Mazak MegaStir will provide its hard metal expertise along with tooling specifically developed for the MELD process that also incorporates the use of friction as part of its solid deposition process.

According to Dale Fleck, General Manager of Mazak MegaStir, the company has the unique ability to provide the complex tooling with the high-strength capability necessary to commercialise MELD’s solid deposition technology. The tooling is made from ultrahard materials such as PCBN and carbide and withstands the extremely high loads & forces necessary for the process.

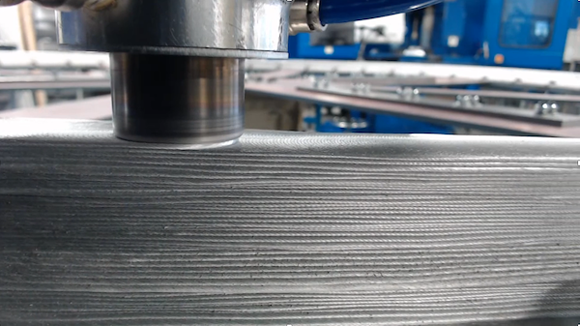

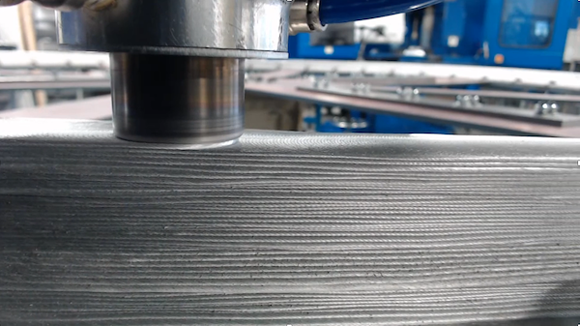

MELD uses a patented Additive Manufacturing technology based on a process similar to friction welding used by Mazak MegaStir, and can be used for the building and repair of metal components using off-the-shelf solid-state materials or powder. The process is capable of additively manufacturing large metal parts due to the fact that it is an open-atmosphere process and is not sensitive to the operating environment or material surface condition.

As layers are deposited during the MELD process, the Mazak MegaStir tooling – operating with applied pressure and frictional load – spins and joins the layers together. The tooling mounts into deposition heads on CNC machine platforms with the ability to feed the metal material down through the center of the head and the tooling.

From its Kentucky facility, Mazak produces over seventy models of turning centres, multi-tasking machines and vertical machining centres, including five-axis models, hybrid Additive Manufacturing processing machines and Swiss turning machines. Mazak maintains eight Technology Centres across North America to provide local hands-on applications, service and sales support to customers.

Download Metal AM magazine