Markforged updates binder in popular 17-4PH stainless steel filament

July 28, 2022

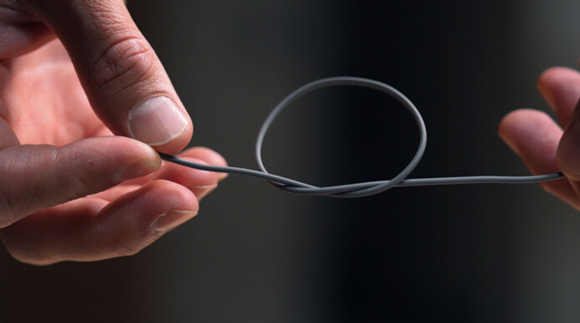

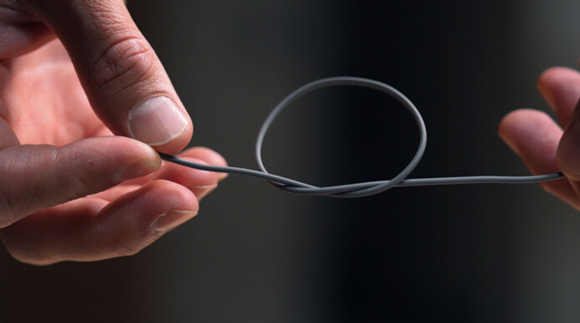

Markforged, Watertown, Massachusetts, USA, has updated its 17-4PH stainless steel filament to offer increased flexibility, whilst maintaining the filament’s original strength and the versatility of the material. The filament, used in Markforged’s Metal X Additive Manufacturing machines, features the same metal powder with an updated binder material.

17-4PH is a general purpose stainless steel alloy, frequently utilised for its strength and ability to withstand significant wear, heat, and corrosion. It can be heat treated, polished, machined, welded, and additively manufactured. It is often used for industrial applications such as grippers, lathe jaws, fixtures, brackets, high-wear tooling, functional prototypes, and custom wrenches & sockets.

Markforged states that the 17-4PH filament is the Metal X System’s most popular metal material. Altering the composition of the binder, with a new material and percent volume, preserves the original filament’s strength, durability, and corrosion resistance, yet offers significantly more flexibility and a less brittle filament. The updated version v2 also features improved mechanical properties with better isotropic characteristics.

The v2 formulation is also faster to load and comes in larger spools, explains Markforged. It can be loaded into an unheated chamber, and additively manufacture for twice as long before the spool of filament must be replaced. This is said to significantly reduce startup and material changeover times.