Mantle highlights TrueShape tooling capabilities in industry collaborations

March 28, 2022

Mantle, headquartered in San Francisco, California, USA, has reported the successful implementation of its TrueShape metal Additive Manufacturing technology, following a number of recent collaborations with industry partners.

Mantle uses its proprietary TrueShape technology – a hybrid material extrusion (MEX), CNC and sinter-based process – in the production of high-precision components for prototype and production tools, moulds, and dies. Using Additive Manufacturing for tooling production dramatically cuts the time and cost of producing these parts.

In the reported collaborations, Mantle additively manufactured tool components with its H13 flowable metal paste, with the resulting parts said to have shown equivalent performance to conventional H13 tool steel.

Conformal cooling enables demanding bio-based polyamide

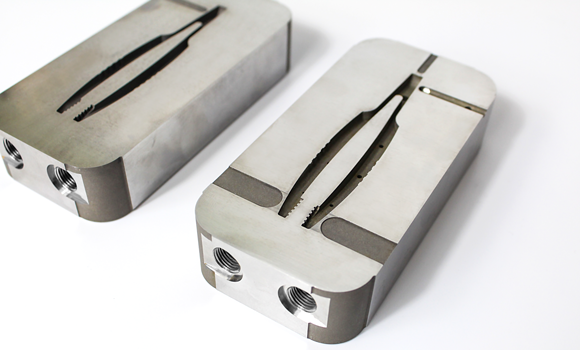

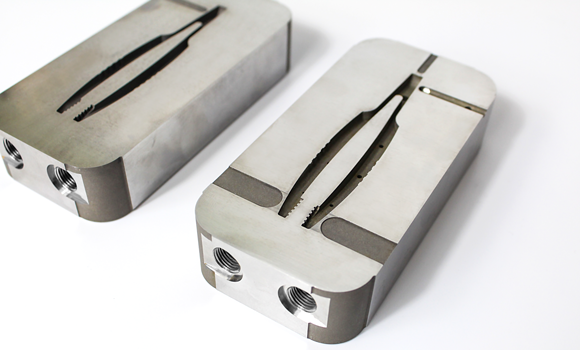

Earlier this year, Mantle teamed up with Westminster Tool, Plainfield, Connecticut, USA, to help them make tooling inserts (core and cavity) so they could quickly mould medical forceps sample parts.

While drilling conventional metal tooling can only produce straight lines and right angles, Mantle’s technology can additively manufacture spiral cooling/heating channels that wrap around hard-to-reach or tall-and-deep geometries. Also known as conformal cooling, this permits moulders to better control mould temperatures, shorten cycle times from 25 to 75%, improve dimensional stability and surface finish, and facilitate demoulding.

Westminster Tool wanted to mould the forceps from a glass filled, bio-based PA11 called Rilsan® FKZM 65 O TD MED, made by Arkema. The material, supplied by a third collaborative partner, Foster Compounds, is focused on surgical device applications, and the new bio-based material aligns with increasing sustainability demand.

According to Westminster Tool’s Manufacturing Engineer, Eddie Graff, a traditional aluminium prototype tool would present difficulties in moulding PA11. However, working with Mantle Graff was able to design the tool inserts to include conformal cooling channels, thus better controlling the cavity temperature. The inserts were additively manufactured in just eighty-six hours.

“In the end, it took us three weeks to go from design to FOT, quality medical parts on a prototype tool,” Graff stated. “It’s incredible.”

Mantle’s metal additively manufactured inserts held a tolerance of +/- 0.038 mm. Because they were made with H13 steel, they allowed Westminster to add a subgate so that the company could mould thousands of parts without the risk of gate erosion.

Improved surface finish and demoulding

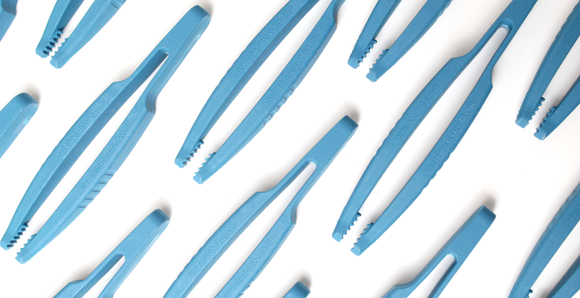

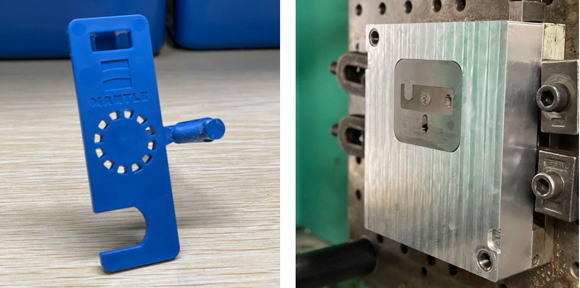

Another recent collaboration with Wepco Plastics, Middlefield, Connecticut, USA, sought to evaluate Mantle’s technology when moulding a cellphone stand, representative of the consumer market, in which surface finish is often critical to quality.

Mantle’s TrueShape technology produces inserts with a smooth matte surface finish, suitable for moulding, with a 1-3μm Ra surface roughness. Wepco mould designer Steven Kronenberger worked closely with Mantle’s Senior Application Engineer Scott Kraemer to design the inserts and conformal cooling channels. Mantle then additively manufactured them in about eighty hours.

Processing setup was said to be swift, and moulding the parts in both blue and black ABS plastic produced smooth surface finishes without the time required for polished aluminium, according to Amanda Wiriya, Manufacturing Support Director at Wepco. She also reported that Wepco’s machine operators were impressed with how easily parts came off the tool.

“We’ve had issues in the past demoulding parts from 3D printed plastic inserts,” she stated. “This was a totally different experience.”

Machining and welding

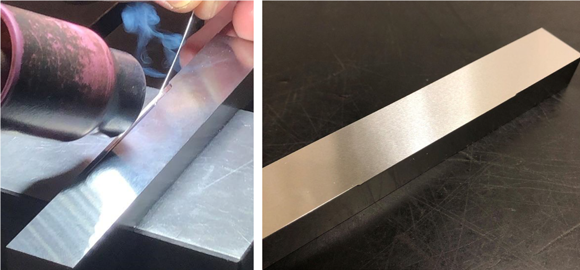

While Mantle’s TrueShape technology can produce accurate tools, the results may still require welding and/or machining to address engineering changes or reconditioning over a tool’s life cycle. A third project sought to verify that Mantle’s H13 material could undergo these processes without any change to existing machining and welding processes.

This study was conducted with Precision Laser Technology (PLT), Rochester, New York, USA, a service provider focused on laser welding, engraving, texturing, and direct part marking for injection moulds and moulded plastics.

For the test, Mantle additively manufactured four H13 test bars, and PLT’s Ron Natale turned to another partner, Kevin Contestabile of Craftsman Manufacturing, Rochester, New York, to precision mill and grind them.

“We wanted to replicate a real-world environment for mould components, one we see as a service provider in the industry,” Natale stated. “This would enable us to test how Mantle’s inserts held up to engineering changes or worn parting lines that require welding. We also wanted to test how easy it would be to machine the insert to tighten up tolerances.”

Contestabile performed CNC machining to add a notch and ground three of the four sides. Natale stated that there was no evidence of pitting and that the material showed no signs of wheel loading or heat generation using conventional grinding methods. PLT welded the notch to simulate adding material for an engineering change or building up a worn parting line in a muold. The material accepted the filler wire readily, and Contestabile post-ground the bar again.

Natale stated that the end results were indistinguishable from traditional H13 tool steel. He concluded, “It was a seamless experience, and didn’t disrupt any of the processes in our shop. There were no requirements for special tooling or alterations to the process because of the material. Performance was consistent with conventional H13.”