Lumafield announces $35M Series B funding round for its industrial X-ray CT platforms

September 12, 2022

X-ray CT technology developer Lumafield, Cambridge, Massachusetts, USA, announced that it has closed a $35 million Series B funding round from new and existing investors, achieved a major new AI-driven performance breakthrough, and appointed two executives to its board of directors. To date, the company has raised a total of $67.5 million.

When Lumafield emerged in April 2022, it offered what it called the world’s first accessible industrial X-ray CT platform for a more affordable price than legacy systems. Now, the company has reputedly made its Neptune scanner over 300X faster, enabling scaling from one-off scans to serial inspection in high-volume manufacturing operations.

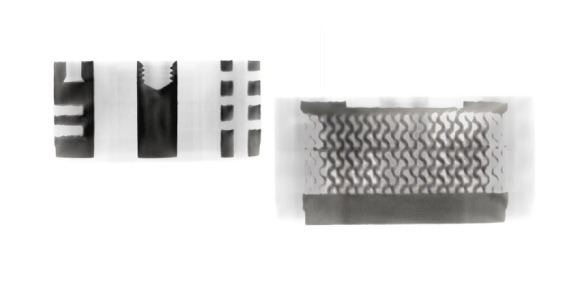

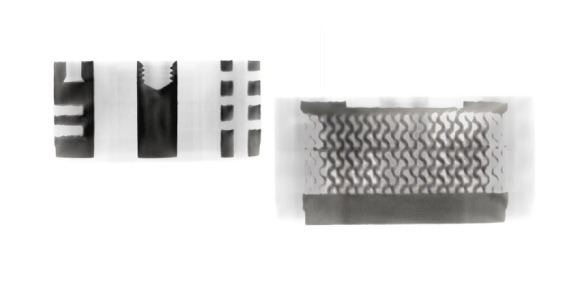

Behind the speed increase is a development in artificial intelligence. CT scanners work by capturing a series of two-dimensional X-ray images from different angles, then reconstructing them into a 3D model using software. Lumafield’s AI allows the company’s reconstruction process to achieve the same results with fewer two-dimensional X-ray images, reducing the time required to run a scan.

New improvements in Lumafield’s software also make it possible to skip certain steps in the reconstruction process before performing automated analysis, thus reducing process time. As a result, scans that previously took several hours are said to now run in a minute or less, making industrial CT a practical technology for quality assurance on factory floors. Combined with factory automation systems, Lumafield’s scanner and software can inspect products at high volume, automatically flagging problems such as dimensional inaccuracies and the presence of pores and cracks.

“Industrial CT has been out of reach for most production lines – until now,” stated Eduardo Torrealba, co-founder and CEO, Lumafield. “With these speed improvements and Lumafield’s low price point, it’s now possible to implement 100% inspection with CT, catching invisible issues before they become costly problems.”

Lumafield also announced the appointment of Victoria Holt and Santo Politi to the company’s board of directors. Holt was previously CEO of Protolabs and is a member of the boards of directors of Waste Management, A.O. Smith, and Piper Sandler. Politi is the founder and General Partner of Series B funding leader Spark Capital, where his investments have also included Oculus, Twitter, Wayfair, and Plaid.

“The manufacturing world is changing dramatically,” added Holt. “Manufacturers are confronted with an increasingly competitive marketplace, radical shifts in supply chains, and ever-higher customer expectations. My experience leading Protolabs gives me an appreciation for the positive impact technology can have on manufacturing. Lumafield offers a technology, a team, and a perspective that promise to reshape the way products are made. I’m very excited to work with Lumafield to realise its vision.