LINK3D’s Digital Factory enables workflow automation for Additive Manufacturing

September 27, 2017

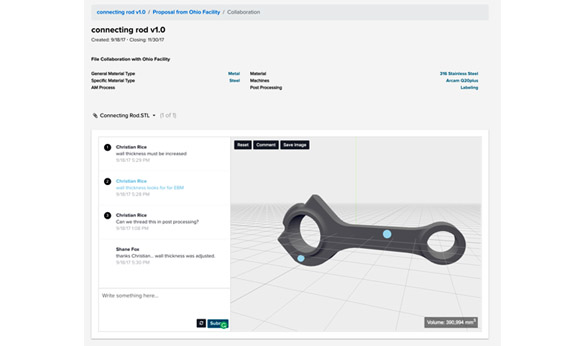

The Project Collaboration Tool in Digital Factory (Courtesy LINK3D)

LINK3D, New York, USA, has launched its Digital Factory, a product designed to enable the automation of Additive Manufacturing workflows. The company launched in early 2017 with its On Demand service, which securely connects engineers to Additive Manufacturing service providers.

Digital Factory SaaS will allow engineering companies to create a virtual ‘digital factory’ to manage their Additive Manufacturing processes, and reportedly brings security, automation, accessibility and traceability to every connecting point within an organisation’s AM ecosystem.

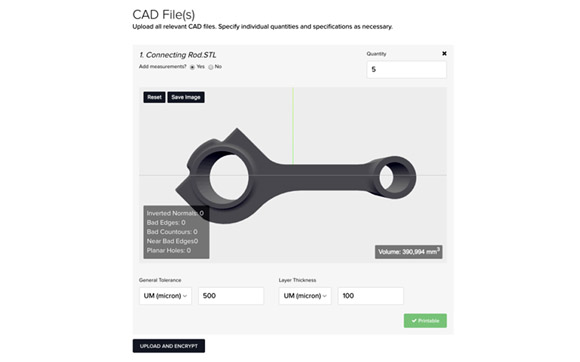

Digital Factory’s Automated File Repair Tool (Courtesy LINK3D)

Following the launch of On Demand, LINK3D’s team began a project to automate a company’s specific AM workflows through data, AI and automation. Through its research, the team reports that it discovered that most companies using AM had encountered critical issues with decentralisation, disconnected silos and manual processes that hindered the full-scale adoption and efficiency of Additive Manufacturing.

To counter these issues, Digital Factory includes features such as a project collaboration tool, API integration for internal and certified vendors, an automated file repair tool, intelligent order routing and assisted or automatic pricing simulations. According to its developers, it is the first product to allow industrial Additive Manufacturing ‘in real-time.’