Lincoln Electric and BPMI to support US Navy with large-scale metal Additive Manufacturing

February 23, 2024

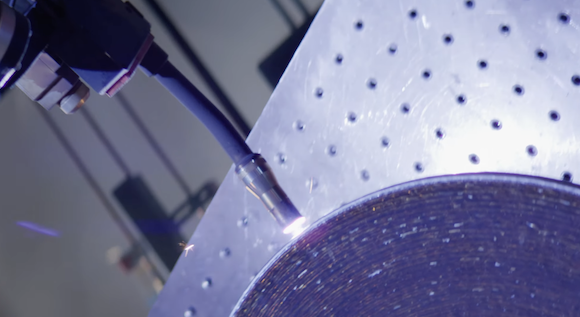

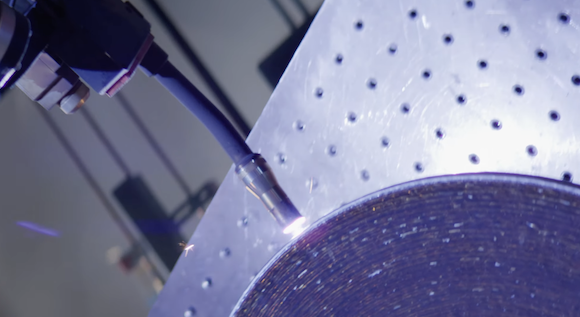

Lincoln Electric, Cleveland, Ohio, USA, has announced that its large-scale Additive Manufacturing solution was selected by Bechtel Plant Machinery, Inc. (BPMI) to support the US Navy. As part of the development programme, Lincoln Electric will additively manufacture propulsion components measuring over three metres in diameter and weighing up to 9,000 kg.

“We are proud to continue expanding our network of strategic programme partners to the US Navy,” commented Barbara Staniscia, BPMI President and General Manager. “Metal Additive Manufacturing is pivotal to driving innovation and supply chain resiliency, enabling the programme to deliver advanced capabilities to the US Navy.”

Mark Douglass, PhD, Business Development Manager, Lincoln Electric Additive Solutions, shared, “We are pleased to be a strategic partner to BPMI and support the US Navy’s goal to accelerate shipbuilding. We believe our advanced manufacturing process, supported by in-house wire feedstock production and industry-leading application, automation and metallurgical expertise can add significant value in meeting the US Navy’s goals.”

Lincoln Electric reportedly operates the world’s largest wire-based metal AM platform at its facility in Cleveland, Ohio, and is fully vertically integrated with high-volume wire manufacturing across a range of alloys, 3D robotic cell integration and proprietary software. The state-of-the-art Additive Manufacturing solution rapidly builds large-scale, metal-based parts directly from CAD files up to eight times faster than traditional casting or forging methods.

Download Metal AM magazine