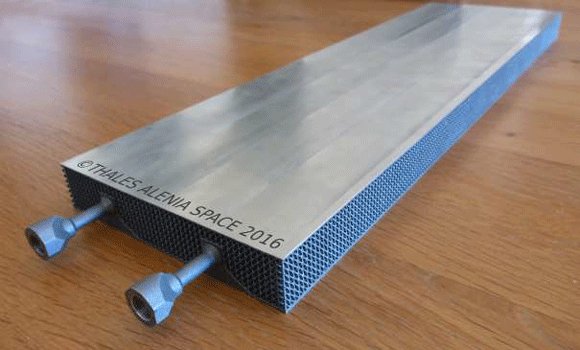

Large scale metal lattice structure for complex satellite part

January 6, 2017

Adimant, a Copenhagen based engineering company providing software and design services for the industrial Additive Manufacturing sector, has reported that it recently worked with Thales Alenia Space in the development of a large scale satellite component.

The part, shown above, is said to be among the largest metal lattice structures manufactured to-date with a post-machined weight of 1.7 kg and bounding box of 134 x 28 x 500 mm.

Thales Alenia Space, Europe’s largest satellite manufacturer, approached Adimant regarding design software issues with a particularly complex satellite part. Thales wanted to print the component in metal, but the design they had come up with was too complicated to be created as a CAD file that could be transferred to the printer.

Adimant’s experience and in-house software allowed the company to solve these issues. “Due to the different competences and tools we have in our company, we are capable of handling designs that would make other software give up,” stated Erik Andreassen, co-founder of Adimant.

“Our main competence is that we can make a design which exploits the full design freedom of AM, both when it comes to topology optimisation and lattice structures,” added Andreassen. Both he and Anders Clausen, also a co-founder of the company, have PhDs in topology optimisation. The third co-founder, Klaus Loft Højbjerre, has in-depth knowledge on metal AM thanks to a PhD in experimental physics and many years of practical experience with metal AM machines from the Danish Technological Institute.