Kanthal launches AM service for heating applications

November 8, 2019

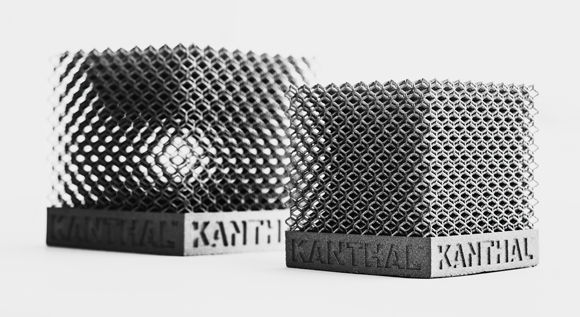

Kanthal, part of Sweden’s Sandvik Group, has introduced a new Additive Manufacturing service for the customisation of heating elements and components. The new service, Kanthal Additive Manufacturing, will offer AM production along with the company’s new iron-chromium-aluminium (FeCrAl) alloy, Kanthal® AM100.

Kanthal has recently been focusing on AM to gain a full understanding of how to best use the its unique materials and expertise in electrical heating solutions to create value for the customer. With superior properties, the new Kanthal AM100 alloy is said to offer new possibilities in high-temperature applications.

Nicklas Nilsson, Kanthal President, stated that he sees a wide number of possibilities as well as great customer value with the new customisation service. “There are basically no limits to what you can design,” he stated. “The possibilities are endless, and once you grasp that, it truly opens up for revolutionary innovation.”

One area of potential noted is the transformation from gas to electric heating, a move that Kanthal believes will feature AM as an integral part. “It has so many benefits, from both a design and a business viewpoint, as well as of course from a sustainability perspective,” Nilsson added. “This technology is the future.”