Kansas Convergence Sciences awardee researchers target AM waste

February 12, 2021

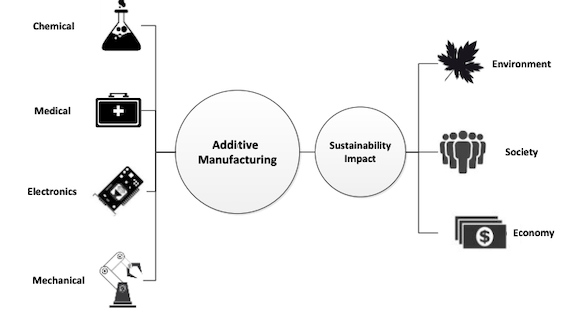

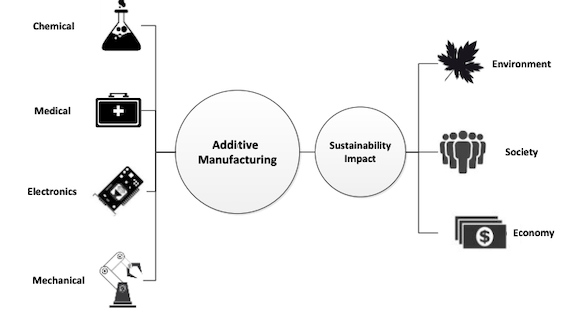

A team of interdisciplinary researchers, the Smart Fusion Material Research Cluster, at Wichita State University, Witchita, Kansas, USA, is working to create sustainable Additive Manufacturing practices that reduce waste.

The project is one of the awardees of Wichita State University’s Convergence Sciences Initiative, an effort to bring the strengths of both faculty and students from a range of disciplines together, giving them support to develop research programmes which drive the diversity and growth of the Kansas economy, while addressing global challenges. Winners of the Convergence Sciences awards will be given $300,000 over three years.

“The traditional ways of making things are based on a subtractive manufacturing method,” stated Dr Gisuk Hwang, principal investigator on the project and the university’s associate professor of mechanical engineering. “To make a cup, you need to remove the parts that you do not need, such as the inside of cup, starting from the solid cylindrical rod. Removing the unnecessary parts generates the waste of the materials. However, Additive Manufacturing can additively build the parts that we need, which do not generate a whole a lot of waste material.”

Currently, the team explains that there aren’t many available options as far as materials for AM; the most common for manufacturing are stainless steel- or nickel-base materials and titanium. Materials such as aluminium and magnesium usually aren’t manufacturable to the required quality. Hwang believes his team has a solution for that.

“We’ve come up with an emerging data analytic algorithm to identify the way that we can print so that we can minimise a lot of trial-and-error practice,” he stated.

The ten-member convergence sciences team includes four colleges at Wichita State (College of Engineering, College of Applied Studies, Fairmount College of Liberal Arts & Sciences, and College of Fine Arts) and two Kansas universities (University of Kansas and Kansas State University).

The team is working to merge its members’ expertise to create an entrepreneurial incubator. As such, its experts run the gamut: a STEM educator, engineers, a physicist to develop quantum-based sensors, a mathematician to run simulations and a government affairs specialist to advise on environmental policy.

“The research component is synergistically implemented into the education component so that whatever they find from the research, we can just push for an entrepreneurship mindset to come up with innovative ideas for business and then economic activities,” added Hwang.

On the STEM education side of this convergence sciences project is Dr Mara Alagic, graduate coordinator for Learning and Instructional Design at Wichita State, who will be working with children and educators throughout their educational careers to make geometry and AM more relatable and accessible. One of the goals of this side of the project is to create STEM education degree programmes at WSU.

“It’s very important for me as I work with teachers to bring examples that are related to real life and real needs,” stated Alagic. “3D printing these days is popular and very relevant for industry in different areas, and we’re bringing that understanding to the classroom. It’s about having that connection with Additive Manufacturing.”