Kallista produces designer tap using 3D Systems’ Additive Manufacturing technology

January 17, 2018

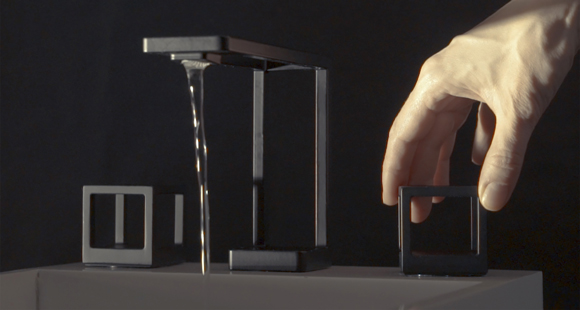

Using AM, Kallista’s designers were able to design without limitations to create an open form and discreet interior channels (Courtesy 3D Systems)

3D Systems, Rock Hill, South Carolina, USA, reports that luxury kitchen and bath product manufacturer Kallista has produced a metal additively manufactured sink tap / faucet using its technology. The Grid® faucet was produced by third-party metal AM service provider 3rd Dimension on a 3D Systems ProX® DMP 320 machine. To avoid rust and corrosion, the tap was produced from 3D Systems’ LaserForm® 316L, a stainless steel 316 powder material.

In deciding to produce the tap’s spout via AM, Kallista’s designers were able to design without limitations to create an open form and discreet interior channels that allow water to flow easily through the base. “Designers usually need to consider a manufacturing process and design around that process,” explained Bill McKeone, Design Studio Manager, Kallista.

“By choosing to produce this faucet via 3D printing, we opened ourselves to limitless design possibilities. 3D Systems’ breadth of materials and technologies allowed us the freedom to create a unique, functional faucet which would not have been possible with a traditional manufacturing process.”

“This is just one example of the value 3D printing brings to a production environment,” David Cullen, 3D Systems (Courtesy 3D Systems)

In addition to the increased design flexibility, developing the product for AM meant that Kallista was able to avoid the common delays of weeks or months needed for any kind of production tooling. “In order to realise the best product, you have to start with the best tools,” added Bob Markley, 3rd Dimension President. “The strength of the 3D Systems technology and materials, coupled with the expertise of our engineers and machinists, allowed us to rapidly produce and deliver these high-end faucets for Kallista.”

“This is just one example of the value 3D printing brings to a production environment,” said David Cullen, Director of Applications Engineering, 3D Systems. “Through the combination of materials, print technology, software and services, Kallista was able to bring their visionary design to market.”