Interspectral adds AI-powered automated anomaly detection to AM Explorer

March 25, 2024

Interspectral, Norrköping, Sweden, has announced the integration of AI-powered automated anomaly detection in its AM Explorer process monitoring and quality assurance software package. With a modular approach to AI, Interspectral aims to accelerate the quality assurance workflow for end customers, reducing the need for manual review and saving both time and money.

“Artificial Intelligence and automated anomaly detection are integral parts of our strategic roadmap. The integration of AI into AM Explorer represents a significant milestone for us and our customers. We are dedicated to providing the AM industry with state-of-the-art solutions, and this new enhancement will greatly improve the automated analysis capabilities of AM Explorer,” stated Isabelle Hachette, CEO at Interspectral.

Accelerating quality assurance is key to fully industrialise Additive Manufacturing. According to various market reports, the cost of quality assurance and post-processing can represent between 30-90% of the total cost per part in metal AM.

“AM Explorer is designed to accelerate the quality assurance workflow, helping our customers cut costs and improve quality. Today, we see a cost reduction of over 50% when introducing AM Explorer into a traditional QA workflow. With our new AI-powered functionalities, we believe these savings will be significantly enhanced,” explained Hachette.

AM Explorer

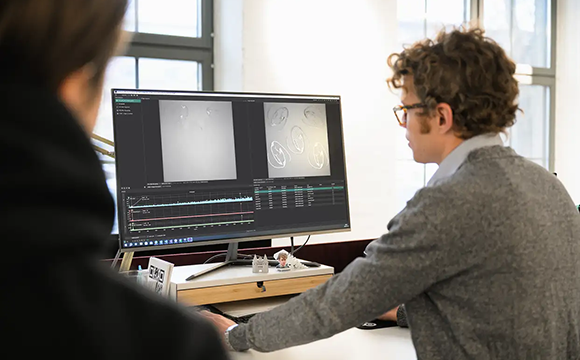

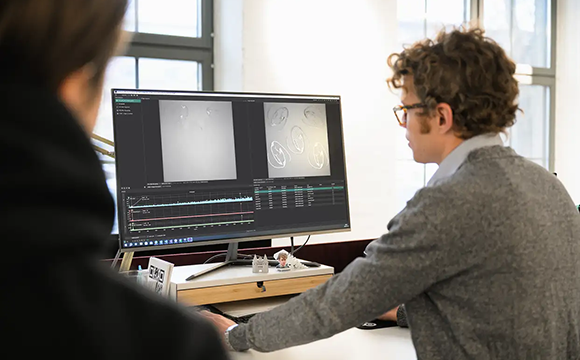

AM Explorer is used by customers worldwide to undertake process monitoring and quality assurance for Laser Beam Powder Bed Fusion (PBF-LB) and other metal AM technologies. With its data fusion and 3D visualisation capabilities, users can explore the complete digital twin of a build job, including data from all process steps, such as simulation, process monitoring, and post-build analysis.

The new AI-module is fully integrated into the EOSCONNECT workflow and performs an analysis on the powder bed images. It can identify the most important and common anomaly classes, including lack of powder, craters, and elevated parts. The module has been developed based on the needs and training data from existing AM Explorer customers, including the French service provider MMB VOLUM-e.

“We are successfully using AM Explorer for quality control in serial production. With help of AI powered automated analysis we will be able to further accelerate our workflow. We look forward to continuing our journey with Interspectral,” stated Clément Barret, at MMB VOLUM-e.

A modular approach to AI

Interspectral adopts a modular approach to AI, allowing customers to choose between pre-trained models delivered by Interspectral or a custom model tailored for a specific machine and material. Customers can also use existing AI models together with AM Explorer.

“We have chosen to adopt a modular approach to AI. Our customers will be able to choose from a variety of pre-trained models developed by Interspectral and our partners. For demanding users, we can tailor our models specifically to the machine, material, and application of the customer,” explained Thomas Rydell, Product & Business Manager at Interspectral.

Download Metal AM magazine