InssTek to ship world’s largest metal DED Additive Manufacturing system to Russia

December 5, 2016

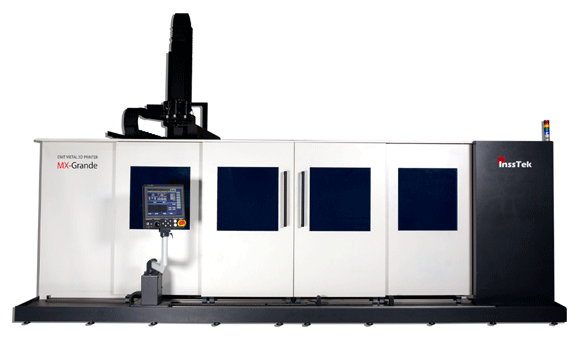

The MX-Grande has a build envelope of 4000 x 1000 x 1000 mm

South Korea’s InssTek has signed a US$2.3 million contract to ship one of its MX-Grande metal Additive Manufacturing system to a customer in Russia. With a working envelope of 4000 x 1000 x 1000 mm, the six-axis MX-Grande is said to be the largest Directed Energy Deposition (DED) type system in the world. The company also announced it has won a bid to supply a German university with an MX-450 system in a $1.2 million deal.

InssTek produce a number of metal AM systems ranging from a compact desktop model to its flagship MX-Grande model incorporating a 5 kW Ytterbium fibre laser.

The company was founded in 2001 and has developed its own patented Direct Metal Tooling (DMT) technology, classified as Directed Energy Deposition in the ASTM standard. The technology can be applied in electronics, automotive, medical, aerospace and defence industries.