Innovation award for VBN Components’ patented metal alloys

November 30, 2018

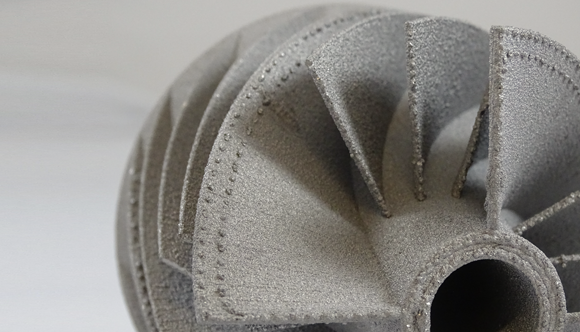

A pump impeller additively manufactured from Vibenite 350, said to be highly corrosion resistant (Courtesy VBN Components AB)

VBN Components AB, Uppsala, Sweden, has received an Award for Innovation from the Working Committee of the Self-employed and Small and Medium-Sized Enterprises within the Social Democratic Party of Germany (AGS SDP). The AGS Innovation Award is given annually to innovative, successful and socially-responsible enterprises or organisations actively participating in their respective market. This year’s awards were made on the theme of “Shaping the future with courage – the digital upheaval in economy and society.”

VBN Components develops and manufactures new, wear-resistant alloys which are designed to enhance lifespan and capacity for industrial tools and components, while optimising material use and production costs. In addition to their extreme wear resistance, achieved by the addition of small, well-dispersed carbides, VBN’s Vibenite® materials range is pore free.

”It means a great deal that VBN Components is being recognised at a European level with this award. Germany is an important business partner to us and the prize will give us new connections on one of Europe’s most important markets,” commented Ulrik Beste, VBN Components’ CTO and Co-founder. The award was presented in an official ceremony on November 29, 2018, at Willy-Brandt House, Berlin, Germany.