Incus is expanding its material portfolio with 99.9% pure copper

February 8, 2024

Incus GmbH, based in Vienna, Austria, is expanding its material portfolio with the progression of 99.9% pure copper material to the production stage. While it has closely collaborated with external partners on copper development, Incus has now initiated its internal R&D activities.

Incus has been focusing on improving the binder system of its lithography-based metal manufacturing (LMM) – defined as a vat photopolymerisation process (VPP) by ISO/ASTM – for nearly a year. After conducting the first furnace runs, Incus was able to achieve isotropic 92% of the electrical and thermal conductivity of conventionally produced copper. Furthermore, the total time spent in the sintering furnace was optimised below twelve hours.

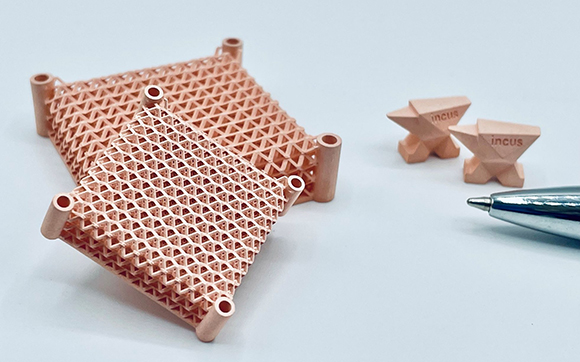

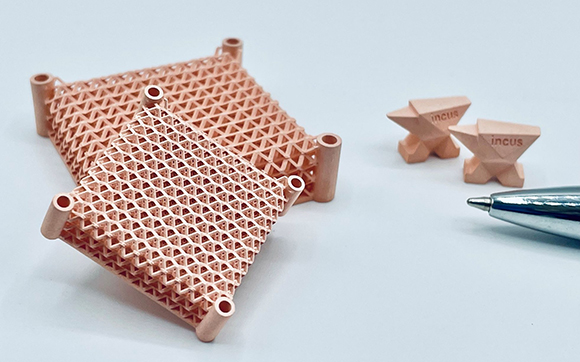

Oxygen-free copper is used in various applications, such as thermal management systems, electrical connectors, and RF communication. Using LMM, Incus can additively manufacture copper pieces with unparalleled surface aesthetics and the highest geometrical complexity. LMM’s strength lies in its ability to eliminate the need for support structures during the manufacturing process, ensuring a homogenous powder distribution free of any defects and the best possible material performance.

The Incus technology offers a high solid loading of up to 60Vol.% of copper powder, enabling the highest density and optimal shape post-sintering. High solid loading is key to achieving the best mechanical properties and preventing deformation during sintering.

Incus has been able to reach such high solid loadings in LMM due to the combination of the binder system and its recoating mechanism. This enables consistent part homogeneity and quality, regardless of part volume. With one parameter set, Incus can manufacture both smaller complex parts and larger volume parts simultaneously.

Download Metal AM magazine