Iconic bike designer looks to bring metal AM bike parts to weekend riders

June 11, 2020

Leading bike designer Dimitris Katsanis, known for his work in designing Great Britain’s Olympic track cycling team’s bikes, which helped win many medals at the Beijing 2008 and London 2012 Olympics, is reported to be using Additive Manufacturing as he aims to build the lightest, fastest bike.

As reported by GE, Katsanis is using GE Additive’s metal AM machines to pursue his aim, where it is believed that the combination of Additive Manufacturing and titanium – which is lighter than steel, stronger than aluminium and popular with racing-bike designers – could have significant implications for the sport.

“The cycling world is obsessed with weight,” Katsanis says. “It is always a main target for any decent new development.” But there have long been barriers to using more titanium in cycling, the report states. The material is about three times the cost of aluminium or carbon fibre, and welding it requires special procedures.

Katsanis is said to have purchased a GE Additive Arcam EBM machine in 2015, and his early efforts resulted in a set of bespoke handlebars aimed at elite racers. However, Katsanis wants the technology to make bigger inroads into the cycling industry. That’s why he’s now additively manufacturing lightweight titanium versions of a number of smaller parts, like pedals and saddle clamps, that could prove appealing to tens of thousands of cycling enthusiasts around the world.

Katsanis’ designs take advantage of AM to make titanium components even lighter than they appear. By using hollow, honeycomb-like interiors, it is possible to produce parts at least 15% lighter than anything comparable, yet strong enough and rigid enough to withstand a bike race.

“He’s passionate,” stated Tom Ibbotson, an engineer with GE Additive who has worked with Katsanis since he purchased his Arcam EBM machine. Ibbotson explains that Katsanis was quick to see the potential of AM and has fully embraced “the freedom of design that we can have – to move beyond traditional concepts and traditional ideas. He’s really going for it.”

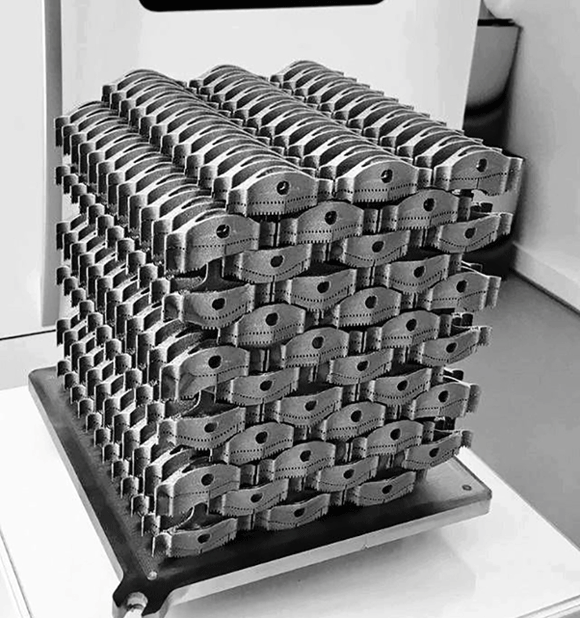

Katsanis has designed a range of saddle clamps – the part that locks the seat to the seating tube – additively manufacturing them in collaboration with a leading European bike-maker. Thanks to topology optimisation, the AM clamps weigh about one-third less than the aluminium model.

As AM technology continues to mature, Katsanis is said to “see potential everywhere”. Faster build speeds could mean lower costs, making parts like these more affordable for weekend riders. In addition, bigger machines will allow designers to pursue more ambitious projects. “Making the entire bike in 3D printed titanium – this can be really mega,” concludes Kastanis.