HP’s novel coating that could enable the free sintering of BJT and MIM parts

June 19, 2023

Metal Binder Jetting (BJT) involves the selective application of a binder layer-by-layer on a powder bed to produce green parts, followed by debinding and sintering treatments. During the debinding and sintering processes, the binder burns out, particle-to-particle necking initiates, and the bonding cross-sectional area increases as sintering progresses. An increase in the bond area leads to an increase in brown part strength. However, the overall tensile strength is compromised due to the prevailing elevated temperature, as a result the parts with overhang features distort/sag under gravity. Traditional methods used to avoid part sag are sintering with live setters or using machined ceramic setters. Distortion/sag during the sintering of binder-powder systems, including MIM and BJT, is inherent and is a fundamentally challenging scientific research problem.

In the open literature, there have been no practical solutions available to sinter as-printed green parts without the use of support structures. Recently, John Samuel Dilip Jangam, Thomas Anthony, Jim McKinnell, Ben Pon, Jake Piderman, and Lihua Zhao, at HP Inc.’s HP Labs invented a shape-retaining-stimulus coating that eliminates the need for support structures during the sintering of copper and stainless steel parts created by Binder Jetting. Their research was published in Solid Freeform Fabrication 2022: Proceedings of the 33rd Annual International Solid Freeform Fabrication Symposium, with the paper ‘Support-free sintering of 3D printed binder jet copper and stainless steel parts’, pages. 1494–1505.

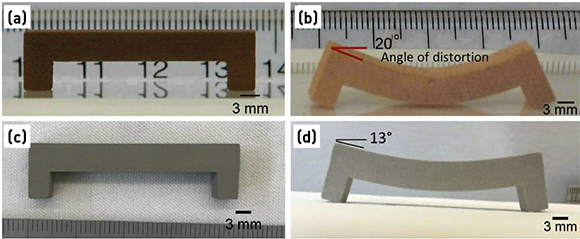

In their study, a simply supported configuration with spans of 28 mm, and 50 mm for copper and 33 mm for stainless steel were used. To ascertain the progress of distortion/sag in copper parts with temperature, the green parts were thermally processed at 500°C to 1040°C. Their results showed an increase in the angle of deflection/distortion from 0° to 20° with an increase in the treatment temperature. Copper green parts were sintered at 1040°C for 4 h in ArH2, and stainless steel green parts were sintered at 1370°C for 2 h, also in ArH2. Fig. 1 shows copper and stainless steel parts before and after sintering. Sintered parts showed a deflection of 20° for copper and 13° for stainless steel.

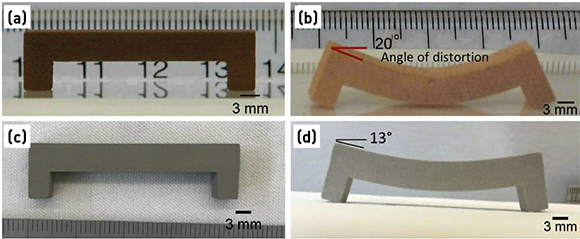

Shape-retaining-stimulus coatings (SRSC) were developed to resist part sag during sintering. SRSC-Cu developed for copper was applied to the green part surfaces (Fig. 2a) and sintered at 300°C for 1 h + 500°C for 2 h + 650°C for 1 h + 1000°C for 30 min, in ArH2. Fig. 2b shows the sintered part with a 28 mm overhang stayed intact without sag. These results profoundly elucidate that SRSC-Cu could eliminate part sag during sintering. Interestingly, SRSC coating on the part surfaces can be cleaned by brushing off or sand blasting (Fig. 2 c). It was also reported that a part with a 50 mm overhang remained intact without sag after sintering.

By subjecting the coated green parts to various thermal treatment temperatures, the authors were able to better understand the mechanism of support-free sintering. According to their findings, the coating forms a strong metallurgical bond with the part surfaces and avoids sagging when treated at 300°C for 1 h + 500°C for 2 h. Concurrently, multi-stage sintering helps to increase the volume of particle-neck-bond providing strength to support itself. When the coated part is heated to 600°C, a chemical reaction in the coating causes it to transform into a porous network, adhering to the part surfaces. In their paper, additional experimental results on parts with overhangs at 30°, 45°, and 60° angles were reported to have sintered without sag.

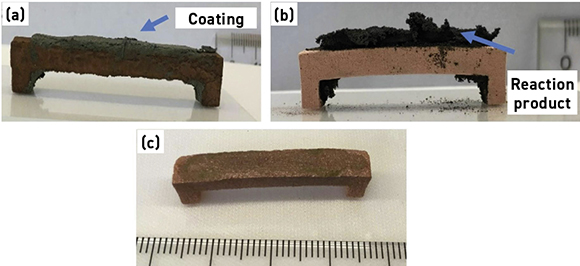

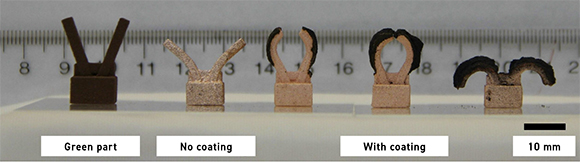

The researchers also investigated support-free sintering of 316L stainless steel parts. SRSC-steel coating, developed for stainless steel, was applied to the green part surfaces, and sintered. Fig. 3 shows green part with SRSC-steel coating (a), after sintering (b) and after cleaning (c). The stainless steel sintered part showed no sag. During the initial stages of debind/sintering, the SRSC ingredients metallurgically bond to the part surfaces and provide the necessary strength to prevent sag under gravity. Similar to SRSC-Cu coating, SRSC-steel coating undergoes a chemical reaction while sintering, and the reaction product is weakly adhered to the part. However, the morphology observed was different. After cleaning and sand blasting there were no traces of prior coating application.

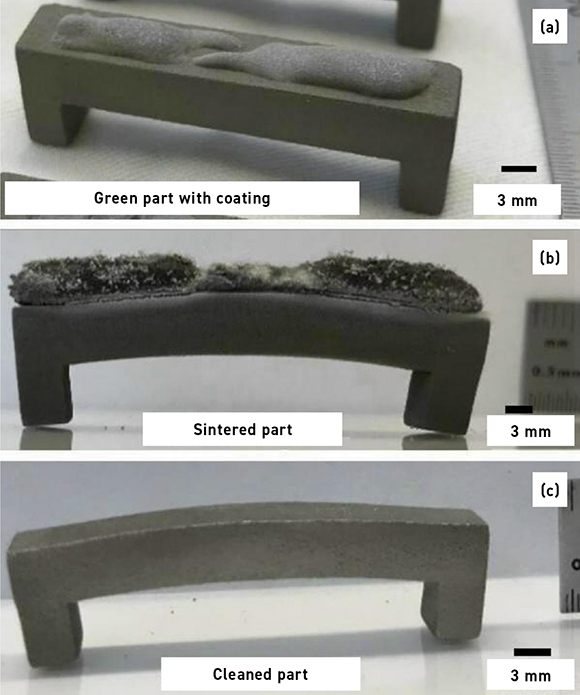

During the development of these shape-retaining-stimulus coatings, certain coating mixture combinations were found to induce positive deformation while sintering. These coatings caused the part to curl up, moving against gravity and countering the natural phenomenon of part sag. With an optimised coating formulation, the researchers were able to tune the extent of deformation in the part. Fig. 4 shows that the shape-inducing-stimulus coating can add a new dimension to the copper green part during sintering. Researchers described this intriguing new phenomenon as ‘4D Metal Printing’, since 3D printed green part is transformed to a new shape by an external stimulus coating during sintering. Further, it was mentioned that shape-stimulus coatings can be extended to make self-assembling metal structures, and the details can be obtained from US patent #US20220226892A1.

In summary, a novel approach was invented to address the sag problem during sintering. Introducing shape retaining and shape inducing coatings can overcome the design limitations and open new opportunities in both the Binder Jetting and MIM industries.

Download Metal AM magazine