High dynamic range in-situ monitoring for wire DED electron beam Additive Manufacturing

March 3, 2023

The pro-beam Group, Gilching, Germany, in collaboration with Xiris Automation, Burlington, Ontario, Canada, has successfully adapted the Xiris XVC-1000 camera for use in the high-vacuum, aggressive environment typical of the electron beam process.

Special measures were taken to protect the camera’s sensitive electronics from damaging radiation and to prevent overheating. A special device was also installed which keeps the camera lens clear of metal fumes for at least eight hours of run time. The companies have stated that they are now in a position to supply this imaging solution to wire-based electron beam Directed Energy Deposition (DED-EB) Additive Manufacturing.

In comparison to alternative DED technologies, based on laser (DED-LB) or electric arc/plasma (DED-Arc) as the energy source, wire-based DED-EB has advantages, including:

- Operates at high vacuum, therefore oxidation is prevented, and no shielding gas is required to achieve high purity builds

- The kinetic energy is transferred to heat in the process zone, leading to high efficiency and no issues with highly reflective materials such as copper or gold

- High energy density enables working with materials with high melting points and high thermal conductivity

- Full control of the energy distribution is possible by customising the energy pattern

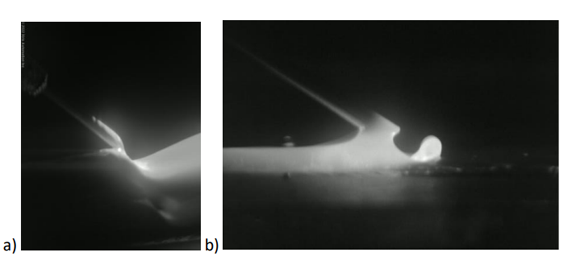

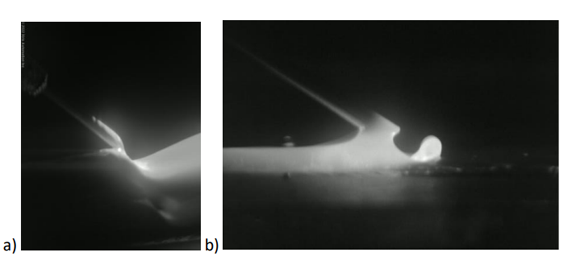

The ability to observe the DED process in real-time, including the melt pool behaviour and the location and the melting of the wire, is an advantage during the development of process parameters and to better understand the process. Furthermore, a clear imaging of the process is required in order to add adaptive control of the process.

Download Metal AM magazine