Heraeus produces ‘world’s largest’ amorphous metal component by Additive Manufacturing

April 9, 2019

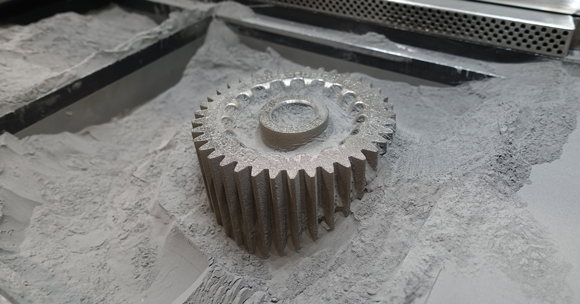

The amorphous metal gear wheel produced by Heraeus (Courtesy Heraeus)

Heraeus, headquartered in Hanau, Germany, has produced what is thought to be the world’s largest amorphous metal component using Additive Manufacturing, in cooperation with advanced materials specialist Amorphology Inc. The component, a gear wheel manufactured by Laser Powder Bed Fusion (L-PBF), was presented at Automate 2019, April 8–11, 2019, in Chicago, Illinois, USA.

In contrast to pure metals and classic alloys, amorphous metals are characterised by an irregular, non-crystalline structure, and combine properties of extreme hardness, high yield strength and high elasticity within one material, which would not normally be feasible. Amorphous metals also offer good corrosion resistance, excellent wear resistance and the elasticity of polymers, have soft magnetic properties and are easy to magnetise and demagnetise. This combination of properties means that for many applications, amorphous metals may be superior to steel, titanium and other materials.

However, due to required cooling rates typically over 1000 kelvin/second for amorphous metals, only small parts have typically been possible using these materials. Using metal Additive Manufacturing, Heraeus was able to produce a part weighing 2 kg – including a weight reduction of 50% achieved by optimising the design, material and production process.

According to Heraeus, the ability to produce large components from amorphous metals opens up many new design possibilities for fields such as the automation and robotics industries.