HBD’s metal Additive Manufacturing boosts pharmaceutical packaging production

March 7, 2024

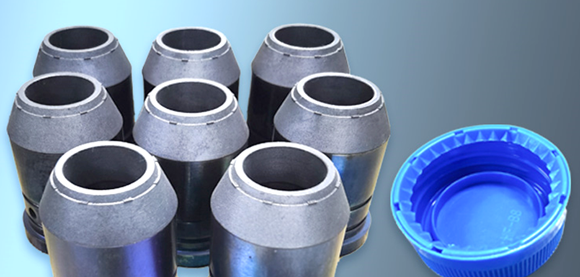

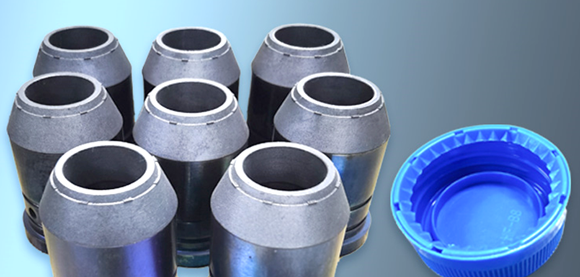

HBD has reported how it used metal Additive Manufacturing to increase the production of bottle caps for a well-established medical company. The work focused on improving the quality and efficiency of pharmaceutical packaging production by using metal Additive Manufacturing to optimise the injection molds used to produce the bottle caps.

HBD explains that the medical company was facing challenges with traditional water-cooled molds, which resulted in issues such as product deformation and inconsistent sizing caused by limitations in the core structure of the molds. These issues lead to ineffective cooling of the cap rim and heat accumulation during continuous production, impeding efforts to boost product qualification rates in an extremely competitive industry.

Taking advantage of metal Additive Manufacturing’s unique design capabilities, HBD incorporated more effective and uniform internal cooling channels in the mold, a solution that proved instrumental in enhancing its efficiency.

Metal Additive Manufacturing enabled intricate cooling channel geometries, facilitating optimal cooling medium contact with the mold surface and increasing cooling efficiency.

Following the integration of HBD conformal cooling channel mold inserts, significant improvements were reportedly observed at the company. Cooling time decreased from 12 to 10 seconds, and molding cycles shortened from 29 to 23 seconds, resulting in an increase in daily qualified output from 19,862 to 25,043 units.

Download Metal AM magazine