Government grant boosts wire-arc Additive Manufacturing in Australia

July 11, 2017

Additive Metal Layering Technologies Pty Ltd (AMLTEC), Sturt, Adelaide, Australia, has been named as one of twenty-four Australian businesses awarded a commercialisation grant under the Australian Government’s Entrepreneurs’ Programme, intended to provide the financial support and advice needed to bring new innovations to market. AMLTEC stated that it will use the AUD 495,000 grant to bring large scale metal Additive Manufacturing to commercial markets.

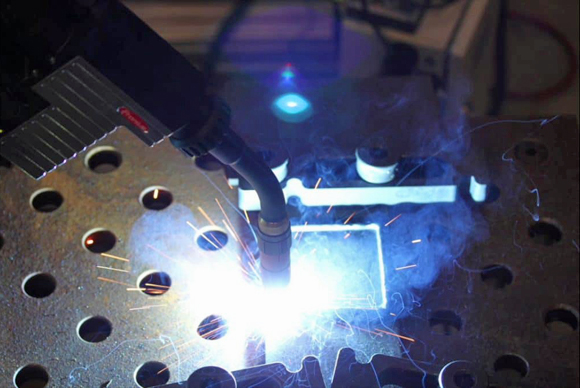

AMLTEC specialises in wire-arc Additive Manufacturing (WAM) for materials such as titanium, nickel alloys, stainless steels and aluminium. The company’s primary markets are in aerospace, automotive, marine, defence, mining (oil & gas) and medical. By using WAM for these applications, AMLTEC states that “wastage of material is reduced by up to 80% and manufacturing times are reduced by 75%.”

Christopher Pyne, Federal Member for Sturt and Minister for Defence, commented, “AML Technologies has been awarded this money from the Turnbull Government to help establish a contract bureau for large scale 3D metal printing. It’s great that they will be supported to undertake commercialisation activities to prove the viability of this great idea.”

Arthur Sinodinos, Australia’s Industry, Innovation and Science Minister added that innovation was vital to improving people’s lives by creating new businesses and helping existing businesses grow. “Ultimately our policies are focused on helping Australians to put more money in their back pocket, through the creation of new jobs and better jobs,” Senator Sinodinos said.

In an interview with Marlborough Express, Andy Sales, AMLTEC’s Managing Director, stated, “Being awarded the grant validates our business plan immensely and provides confidence in the market place and for our small numbers of investors.”