GKN Powder Metallurgy partners with Workerbase on data-driven manufacturing

June 4, 2020

GKN Powder Metallurgy and Workerbase have entered a partnership which aims to accelerate the transformation of the manufacturing industry and prepare for the new business environment post-COVID-19. Under the partnership, the two companies have created what is described as an agile, data-driven production system.

The coronavirus (COVID-19) pandemic has had a significant short- and long-term economic impact on the global manufacturing industry. In a recent survey, the National Association of Manufacturers revealed that, as of March 2020, 53% of organisations in the manufacturing sector expected COVID-19 to change their operations over the coming months and 35% are currently facing supply chain disruptions.

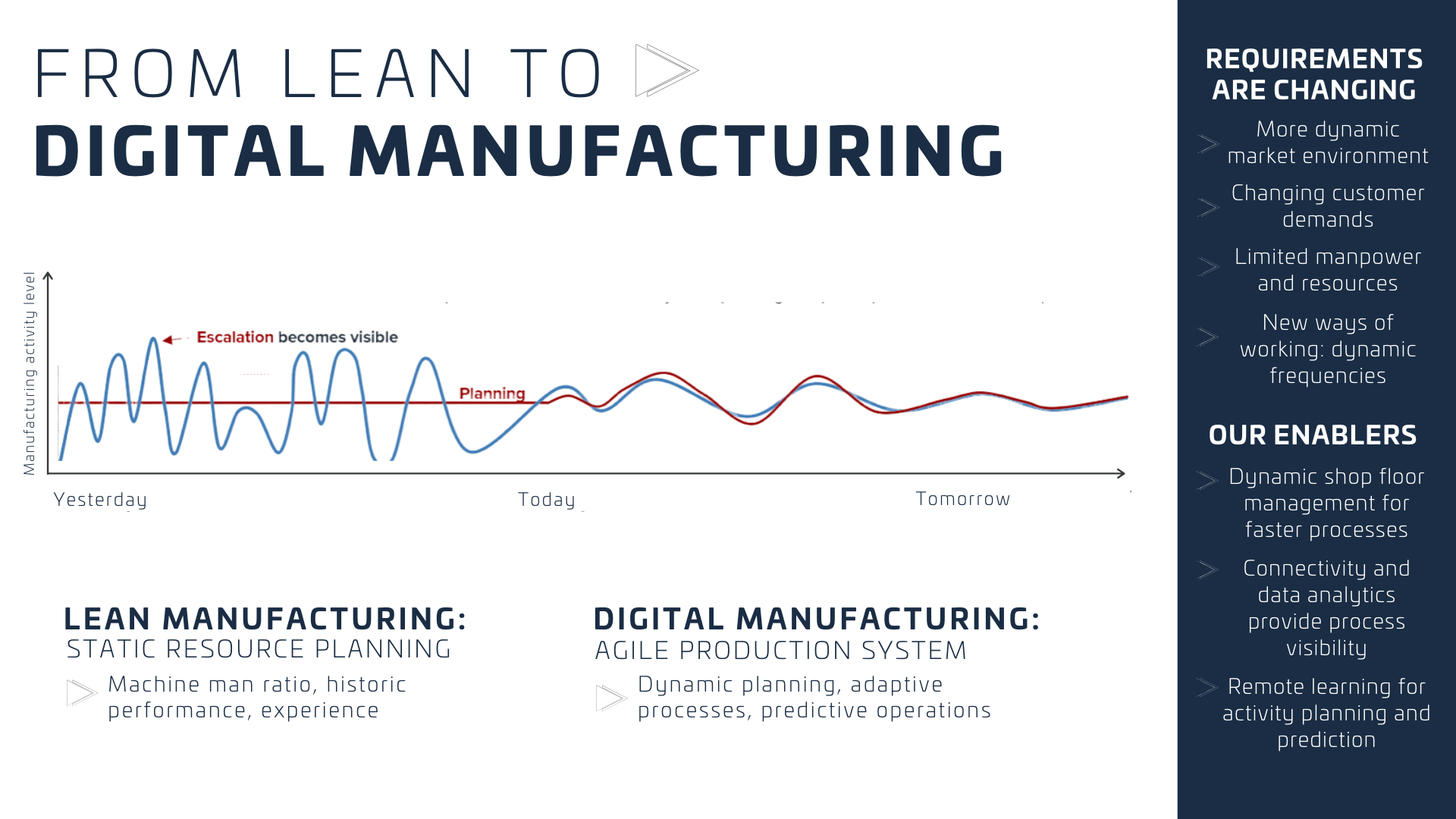

The ability to operate in a rapidly changing business environment, explained GKN Powder Metallurgy, requires organisations to adapt quickly. Increasingly, dynamic customer requirements are driving increased complexity and the need for shorter development and product life cycles. COVID-19’s impact on the supply chain has accelerated these trends and many companies now need to adapt to increasingly challenging market conditions.

Through fifteen years of research and implementation, GKN Powder Metallurgy stated that it has identified the most important question that manufacturing companies must ask themselves: “How can we acquire real-time data from production processes for full production transparency while still empowering our employees to act on the data in real time?”

The new system developed by GKN PM and Workerbase, a leading software provider in the field of agile production systems, is said to implement adaptive processes that allow for quick responses to evolving customer requirements and increasing competitiveness, while reportedly adding value for both shareholders and employees.

“Agile manufacturing has revolutionised our production and has structured how we want to run our operations in the future,” commented Paul Mairl, Chief Digital Officer, GKN Powder Metallurgy. “The new normal of manufacturing requires a new way of working. Our partnership with Workerbase is an important step on our journey to create a new vision of manufacturing operations: combining a data-driven culture with the best technology and technical solutions.”

Norman Hartmann, CEO and co-founder of Workerbase, added, “Today’s competitive markets are accelerating the need for flexible and agile production processes to cope with increasingly challenging customer requirements. We are committed to helping our customers along their journey to becoming a digitally-driven business and we are proud GKN Powder Metallurgy shares our vision for the factory of the future.”

“GKN Powder Metallurgy’s ability to move fast through digital manufacturing is a perfect fit for us,” he continued. “Our customers can now benefit from GKN Powder Metallurgy’s experience and can explore all aspects of our solution in a revolutionised new type of production environment.”

According to the partners, for the new way of working in manufacturing, the traditional role- and hierarchy-based organisational structure is replaced by a setup which is skill- and competency-based.

This organisational move relies on employees taking personal responsibility for their own performance and a self-learning working environment. By utilising technology like mobile devices on the production floor, employees are said to be able to challenge their skill levels and increase their productivity by performing work in a more efficient environment.

While digital manufacturing has made significant improvements to operations in the past, GKN PM stated that recent industry-changing circumstances have shown that a data-driven approach is now more crucial than ever to any production-based organisation. An agile manufacturing strategy is expected to provide the greatest opportunity to reinvent the way companies operate.