GKN announces multi-year partnership with Panasonic Jaguar Racing

September 28, 2017

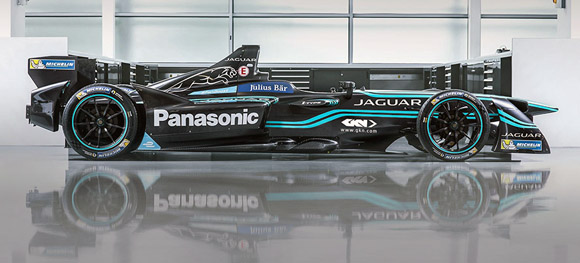

The GKN Group logo features on the livery of the 2017/18 I-TYPE race car (Courtesy GKN)

GKN has agreed a multi-year partnership with Panasonic Jaguar Racing, which will see the global engineering group provide design, manufacturing and consultancy services to the Formula E team. The partnership was announced at the Frankfurt Motor Show in advance of the 2017/18 FIA Formula E championship, which commences in Hong Kong on December 2, 2017.

GKN will provide the team with technical consultancy and new technology, from driveshafts and differentials to the development of components using Additive Manufacturing, for the Jaguar I-TYPE. GKN Driveline will also advise on the development of the I-TYPE’s all-electric powertrain.

Phil Swash, Chief Executive Officer of GKN Driveline, commented, “We have been following the development of Formula E since its inception and have been impressed by how quickly the series has established itself as a competitive and exciting racing series. GKN is excited to be involved in this electric technology showcase and to continue its activities in global motorsport.

“As a world leader in advanced drivelines, lightweight structures and state-of-the-art electrified systems, GKN is proud to join Panasonic Jaguar Racing in its mission to innovate and inspire on the world stage. We can’t wait to get racing in Hong Kong.”

Under the terms of the partnership, the GKN Group logo will feature on the livery of the 2017/18 I-TYPE race car, as well as on all driver helmets and suits, team kit and merchandise.

James Barclay, Panasonic Jaguar Racing’s Team Director, added, “We are honoured to welcome GKN to our team – a company that will bring its expertise and experience to the race track. They share our passion to inspire the next generation of engineers. At Panasonic Jaguar Racing, we want to be successful on and off the track and we look forward to driving forward together in this multi-year partnership.”

GKN and Jaguar first partnered in 1935, when GKN supplied driveline technology to the first SS Jaguar saloon. Today, GKN supplies every Jaguar model on the market with a range of driveline technologies, including high performance CV Joints and intelligent all-wheel drive systems.