GKN Aerospace’s successful lightweight Turbine Rear Structure test

March 14, 2022

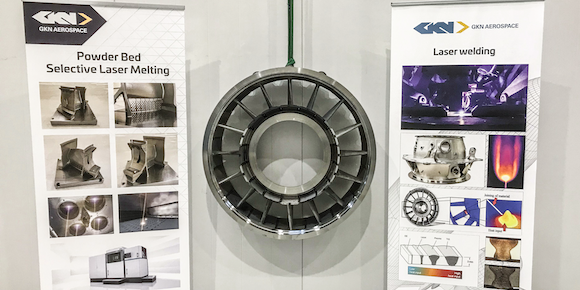

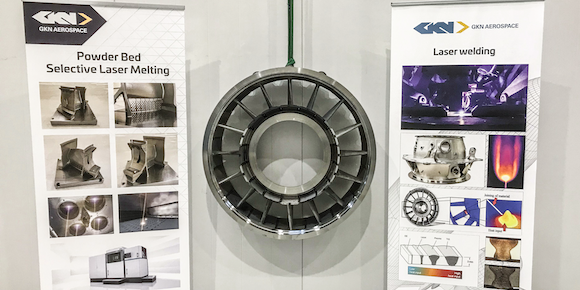

Engineers at GKN Aerospace’s facility in Trollhättan, Sweden, are said to have successfully tested a new lightweight demonstrator of a Turbine Rear Structure (TRS) as part of the Clean Sky-2 Engines research programme. The purpose of a TRS is to manage the flow from the engine’s low-pressure turbine and maximise the axial thrust, a key component in improving the efficiency of an aero engine.

Using a novel metallic alloy with higher temperature capability, as well as Additive Manufacturing and metal casting technologies, the resultant part was shorter and lighter than its traditional counterpart. The optimised balance between aerodynamic performance, weight and mechanical properties demonstrates a 14% weight reduction potential, which would contribute to lower carbon emissions of the engine.

The complex component was manufactured at GKN Aerospace’s Global Technology Centre in Sweden. Collaboration partners include the regional manufacturing technology centre PTC/Innovatum. Aerodynamic validation took place at a test facility at Chalmers University, funded by Vinnova through the SE NFFP programme. Brogren Industries (SME), also funded by Vinnova in the national SE Innovair programme INTDEMO MOTOR, provided supporting activities.

“At GKN Aerospace we put a sustainable future of aviation at the heart of our business and collaboration in the aerospace eco-systems is key to achieve this,” stated Henrik Runnemalm, VP, GKN Aerospace’s Global Technology Centre. “The new TRS demonstrator is a great example of how National, Regional, EU and industry-funded activities are coordinated towards final validation of an innovative concept that will contribute to our net-zero journey.”