GKN Aerospace adds two NXG XII 600 metal Additive Manufacturing machines from Nikon SLM Solutions

September 21, 2023

GKN Aerospace is reported to be acquiring two new NXG XII 600 metal Additive Manufacturing machines from Nikon SLM Solutions (formally SLM Solutions), based in Lübeck, Germany. Of the two systems ordered, one will be used for the production of Inconel In718 parts, and the other for titanium Ti64.

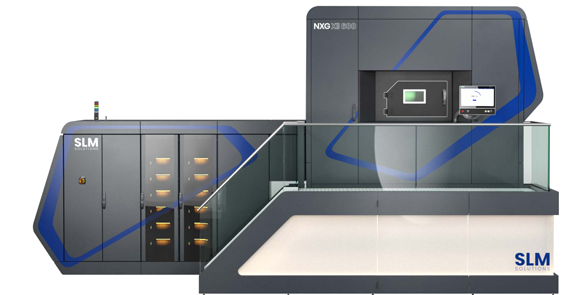

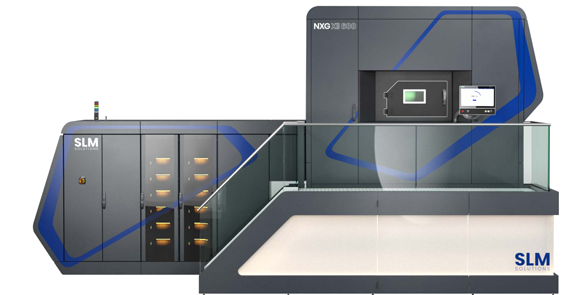

The NXG XII 600 is a Laser Beam Powder Bed Fusion (PBF-LB) machine that has a build envelope of 600 x 600 x 600 mm, allowing for the production of large-scale components. It is equipped with twelve 1000 W lasers, which the company claims is five times faster than a four-laser machine and up to twenty times faster than a single-laser system.

“Partnering with Nikon SLM Solutions is a key milestone in our journey to create better, more sustainable aerospace products,” stated Martin Thordén, VP of Permanova, the newly formed business unit for material solutions within GKN Aerospace. “This collaboration provides us access to cutting-edge Additive Manufacturing capabilities necessary to propel us towards our net zero ambition.”

GKN Aerospace is an aerospace supplier with 38 manufacturing facilities in 12 countries, catering to over 90% of global aircraft and engine manufacturers. It has been involved with Additive Manufacturing technology for more than two decades.

Sam O’Leary, CEO of Nikon SLM Solutions, shared, “Nikon SLM Solutions is honoured to join forces with GKN Aerospace. Integrating our NXG XII 600 system symbolises the future of aerospace, driven by leading-edge technology. As we step into this pivotal phase, our joint capabilities will undoubtedly set new benchmarks in aerospace manufacturing.”

Download Metal AM magazine