GE’s aerospace consortium produces AM part for Clean Sky 2 programme

October 18, 2022

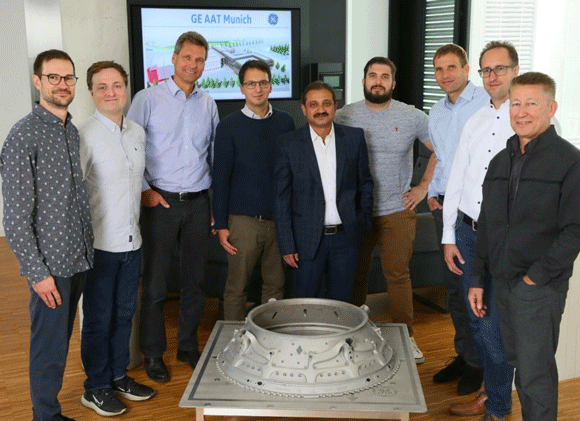

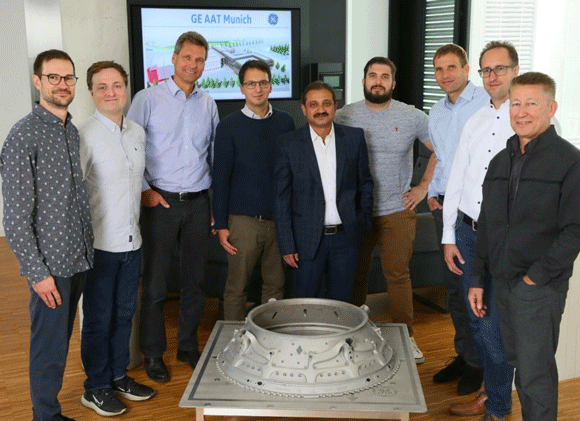

GE Additive has announced that the GE Aerospace Advanced Technology (GE AAT) consortium, Munich, Germany, has additively manufactured a 1 m nickel alloy 718 aerospace component as part of the Clean Sky 2 Programme.

The Clean Sky 2 programme is funded by the European Commission and European aerospace industry and is made up of big industry players and subject matter experts along with academic research bodies across Europe. The programme is integrating, demonstrating, and validating technologies capable of reducing CO2 emissions as well as nitrous oxide (NOx) and noise emissions by up to 30% compared to 2014 ‘state-of-the-art’ aircraft.

The GE AAT Munich consortium leads three core partnerships in the Clean Sky 2 Programme to identify engine hardware, benefits, design, and manufacturing processes and, connected to the programme’s goals, collaborate closely with GE Aerospace’s sites in Italy, Czech Republic, Poland and Turkey, as well as external partners. One of the GE AAT partnerships is the Turbine Technology Project (TURN), which was set up to accelerate technology maturation for future aero engines.

In response to a Clean Sky 2 call for proposals, in 2018 a consortium of Hamburg University of Technology (TUHH), TU Dresden (TUD) and technology company Autodesk, was selected to support GE AAT Munich for the design and manufacturing of a large-scale metal AM component – the Advanced Additive Integrated Turbine Centre Frame (TCF) casing – the MONACO project. This also included the design and production of coupons and critical parts, validation and qualification, and the final delivery of the full-sized metal additively manufactured casing.

The large-format TCF casing produced using GE Additive’s Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing technology is reported to be one of the largest additively manufactured parts produced for the aerospace industry. It is designed for narrow-body engines in which the part is approximately one metre or more in diameter. Having this single-piece design solution to produce this kind of large format engine hardware with reduced cost, weight and manufacturing lead time gives a competitive business advantage.

“We wanted to reduce the weight of the part by 25%, but also improve the pressure losses of the secondary air flow as well as a strong reduction in part count to improve maintenance,” stated Dr Günter Wilfert, GE AAT Munich’s technology and operations manager. “The team can be proud of the results. With the final print of the full casing, they were able to prove the values. Those targets were achieved and surpassed. We were able to reduce the weight by around 30% in the end. The team also reduced the manufacturing lead time from nine months to two and a half months, by approximately 75%. Over 150 separate parts that make up a conventional turbine centre frame casing have been consolidated into one single-piece design.”

In order to ensure that all the engineering requirements were met, including a performance benefit of 0.2% in specific fuel consumption, the design was reviewed by experts from across the team for Technology Readiness Level (TRL) and Manufacturing Readiness Level (MRL) 4 and multiple manufacturing trials were performed to meet hardware quality and incorporate the manufacturability of MRL4.

The turbine centre frame – an inherent component of modern, turbofan aircraft engines – serves as a duct for the hot gas that flows from the high-pressure turbine into the low-pressure turbine. Conventionally, they are manufactured by casting and/or forging, followed by additional machining steps. Due to requirements on airworthy hardware in the highly regulated aerospace industry, the number of approved vendors for casting and forging parts is limited. This creates long lead times and high costs.

These challenges, and the fact that a turbine centre frame isn’t a rotating part, made it an ideal candidate for AM. This new Additive Manufacturing design solution on engine frames is not limited to turbine centre frames for future engines; it can be leveraged to existing and legacy engine centre frames. The proposed design features can also be transferred and/or scaled to turbine rear frames (TRF), low pressure turbine casings and turbine mid frames (TMF).

Ashish Sharma, an advanced lead engineer on the GE AAT Munich team, commented, “People already want to know how this part has been made and how the design and technology could translate to their industries. Our strategy all along was to make sure that the component design meets aerospace engineering requirements and Clean Sky 2 goals, but it could be easily translated to other similar segment engines, and adjacent businesses and sectors.”

The project employed a multi-disciplinary iteration loop setup to design the hardware and leveraged lean manufacturing concepts, processes and tools to reduce design iteration time. Many design features and solutions were considered and introduced to reduce pressure, thermal gradient and stress.

Dr Dirk Herzog, interim professor at TUHH’s Institut für Laser- und Anlagensystemtechnik, said, “Due to the size of the part, it was necessary to evaluate design concepts by manufacturing segments at first, validate their performance and from there learn how to transfer to full scale. A lot of effort has been invested from all of the team members over the course of the last three-and-a-half years to advance us to the point where we were fully confident to have the design and the DMLM process ready for the final print. To finally see the physical part being built successfully is very rewarding.”

At the beginning of the TURN programme, GE AAT Munich explored the design space and performed multiple trade studies leveraging advanced technologies such as Additive Manufacturing. The GE AAT Munich team was able to lay down a technology maturation plan to advance the art of making TCF cases. Finally, when the consortium started to support the technology maturation plan, AutoDesk brought tools to optimise additive design, TUHH added an AM machine for initial build trials and TUD’s experts built an aero/thermal rig with high-quality instrumentation devices for validation – which combined to produce a successful 3600 single-piece additive TCF case on the first attempt.

Thomas IIzig, Eike Dohmen and Sarah Korb, TUD’s team of scientists, noted, “The biggest challenges to validating additively manufactured hardware is that we are not allowed to scale up or down, as this changes the surface finish, which reflects in measurement data translated to product. We contributed our unique experience in testing print trials for mechanical strength, thermal emissivity and aero/thermal validation.”

“The team went ahead and designed and manufactured a novel three-hole probe to measure pressure loss on the additive TCF casing, which demonstrated a reduction of around 90% in pressure drop compared to a conventional design. The TCF casing underwent extensive aero/thermal and mechanical testing to meet engineering requirements,” they added.

GE Additive explains that Autodesk’s role in this research was to develop a lightweight, high-performance turbine centre frame casing by optimising the structural and fluid performance while contributing to consolidating over 150 parts into a single component. Team Autodesk was stated to be instrumental in taking challenges to design components utilising their software tools to meet programme requirements.