German power plant uses metal AM heat shields and vanes in natural gas turbine

November 10, 2016

The Berlin Mitte power plant

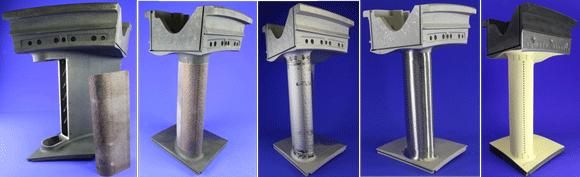

The Berlin Mitte plant, operated by the German power company Vattenfall, is using additively manufactured first-stage heat shields and first-stage vanes inside a natural gas turbine used in a large power plant near Berlin. Developed by GE, the system incorporates the world’s largest AM parts found in any commercially operated gas turbine. Each part is said to weigh 4.5 kg and is around the size of a laptop. Together these parts help the turbine run more efficiently and burn less gas.

“3D printing is often thought of in terms of very small, complex components. We’re proving now that actually, you can commercially manufacture large pieces for turbines,” stated Wolfgang Muller, product line leader of GE Power Services’ gas turbine e-fleet. The turbine has been in operation since September 2016. “It’s a very important, district-heating power plant. It heats the capital’s feet,” added Muller.

When operators start the machine, the heat shields, which are typically made by casting, reach 1,000°C and must be cooled by air. The parts can handle the heat since the machine blows a relatively cooler air of about 400 to 500°C through channels cut into the components to lower their temperature. However, this cooling also reduces the turbine’s efficiency.

The world’s largest AM components found in any commercially operated gas turbine (Courtesy GE Power Services)

The use of Additive Manufacturing therefore allows GE engineers to create much more complex pathways than traditional metal casting. The structures include intricate air passages that cool the components more efficiently. Muller added that when all fifty or so heat shields on the turbine are additively manufactured instead of cast, they reduce cooling flow by more than 40%. “That’s millions of dollars in fuel-cost savings per year,” Muller adds. One turbine typically consumes 10 kg of fuel every second.

One of the hottest components in an operating turbine is the first-stage vane. By additively manufacturing portions of the vane, GE engineers have achieved a 15% reduction in the need for cooling air, which equates to approximately $3 million in fuel savings per year.