GeonX launches new technology for rapid simulation of Additive Manufacturing at Rapid+TCT

May 18, 2017

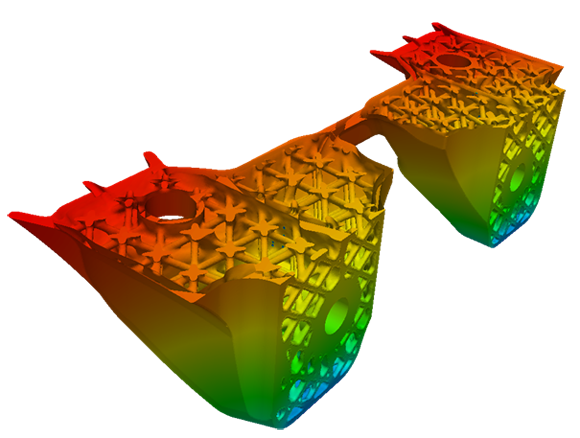

By using simulation to reduce trial and error in large component manufacture, companies may be able to decrease cost and production time (Courtesy GeonX)

GeonX, Gosselies, Belgium, launched its latest technology for Additive Manufacturing process simulation at Rapid+TCT, held in Pittsburgh, Pennsylvania, USA, from 8-11 May, 2017. The new software, Virfac iAM, incorporates the next generation of GeonX’s solver engine and is dedicated entirely to process simulation for Additive Manufacturing.

Since 2012, GeonX has been developing and providing scientific software for the simulation of Virtual Manufacturing processes in welding, machining, heat treatment, damage tolerance and Additive Manufacturing. The company’s Virfac® software comprises an intuitive CAD-based user interface and parallel non-linear finite element thermo-mechanical-metallurgy solver for the simulation of Virtual Manufacturing processes in welding, machining, heat treatment, damage tolerance and Additive Manufacturing.

By using simulation to reduce trial and error in large component manufacture, companies may be able to decrease cost and production time and minimise prototyping, project development and overall time to market. Virfac iAM uses GeonX’s Barracuda solver, which runs on GPGPU (General-Purpose Computing on Graphics Processing Units) processors to bring teraflop computing to desktop. According to GeonX, the new solver offers increased processing speeds of between 100-1000 times faster than conventional finite element solvers.

During Rapid+TCT 2017, GeonX also announced a new partnership with IREPA Laser, Illkirch-Graffenstaden, France. Under the partnership, the two companies will work together to use process simulation to predict distortion levels in large components manufactured by Laser Metal Deposition (LMD).