Gefertec & Linde to investigate influence of process gas and oxygen on AM

January 17, 2019

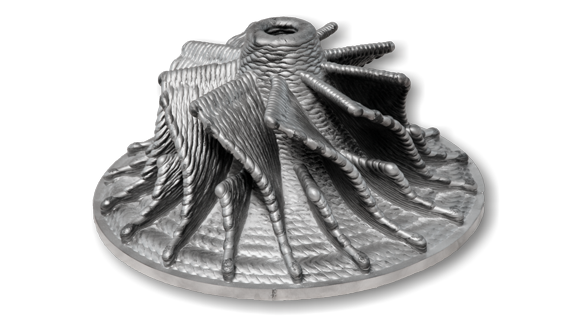

An sample impeller produced on a Gefertec 3DMP electric arc welding system (Courtesy Gefertec GmbH)

Gefertec GmbH Berlin, Germany, and Linde AG, Munich, Germany, are cooperating to investigate the influence of process gas and oxygen percentage on the metal Additive Manufacturing process. Gefertec’s 3DMP® technology uses electric arc welding to additively manufacture parts by welding wire feedstock layer by layer; the result of the arc welding process depends heavily on various parameters – especially the process gas.

The companies will investigate the influence of both welding parameters and process gas on final parts, with further partners on the project including MT Aerospace AG, which will perform mechanical testing on the produced parts, and Fraunhofer IGCV, where the AM of parts will take place on a Gefertec system.

The goal of the project is the production of larger parts at high production speeds, in titanium alloy Ti6Al4V. Ultimately the companies plan to produce products which meet the quality requirements of the aerospace industry.