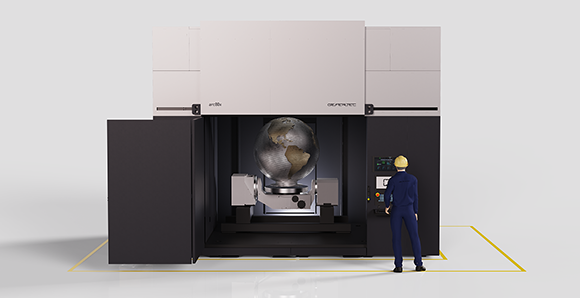

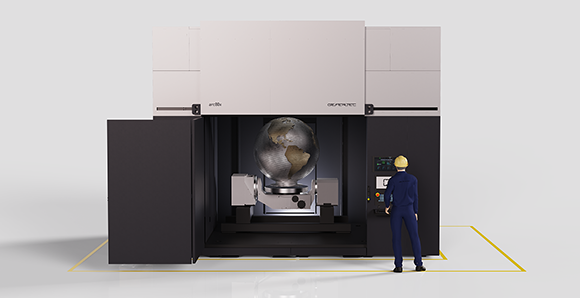

Gefertec launches arc80X Wire Arc Additive Manufacturing machine

March 7, 2024

Gefertec GmbH, Berlin, Germany, has announced its new arc80X Wire Arc Additive Manufacturing (WAAM) machine is now available.

The arc80X’s modular design offers a selection of welding systems from a variety of manufacturers, allowing customers to design a machine suited to their requirements. This flexibility also allows it to be upgraded or converted if customers wish to implement new functions.

The arc80X features automated tool measurement, gas nozzle cleaning, wire cutting and the replacement of wear parts. These functionalities are reported to increase efficiency and reduce manual effort.

Integrated process monitors records and stores all relevant data during the build process. This allows for comprehensive documentation for quality assurance and process optimisation. Additionally, the pyrometer integrated into the arc80X and the active component cooling enables reliable and efficient temperature management of the part.

Adjustable automatic routines react to ignition failures during the production process and keep it running. In addition, the titanium module enables the manufacture of components in a closed inert gas atmosphere, which is essential for the processing of sensitive materials.

The arc80X offers a wide range of table options, from five-axis simultaneous machining to 3+2 to pure three-axis machining. Customers can determine the capabilities of their machines according to the needs of their parts.

Download Metal AM magazine