GE researchers developing portable water-producing prototype using AM

February 8, 2021

The Defense Advanced Research Projects Agency (DARPA), an R&D agency of the US Department of Defense (DoD), has selected a team from GE Research, GE’s tech development arm based in Niskayuna, New York, USA, to lead a new four-year, $14.3 million Atmospheric Water Extraction (AWE) project. Called AIR2WATER (Additively Manufactured, Integrated Reservoir to Extract Water using Adsorbents and Thermally-Enhanced Recovery), the programme will work to simplify the transport of potable water to troops in the field, while addressing water scarcity around the world.

According to the World Wildlife Fund, more than 1.1 billion people do not have access to water; approximately 2.7 billion experience water scarcity. The selected team of GE researchers, together with scientists and engineers from the University of California at Berkeley, University of Chicago, and University of South Alabama, will develop and design a highly compact, portable device that can produce clean, safe water out of air.

As stated in an Army Environmental Policy Institute report, 10–12% of United States Marine Core casualties in Iraq and Afghanistan were brought about in the delivery of fuel and water. The prototype that GE researchers are developing could prove a transformational development, drastically reducing, even potentially eliminating, the need for the distribution of water by providing a ready source of clean water directly where troops are stationed.

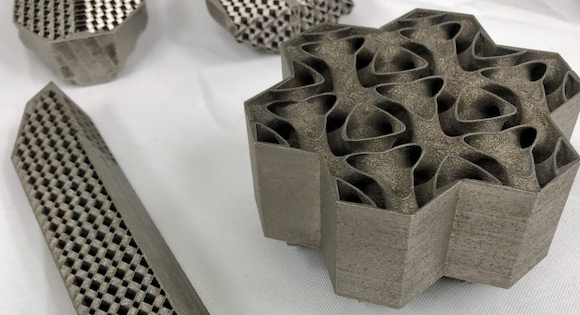

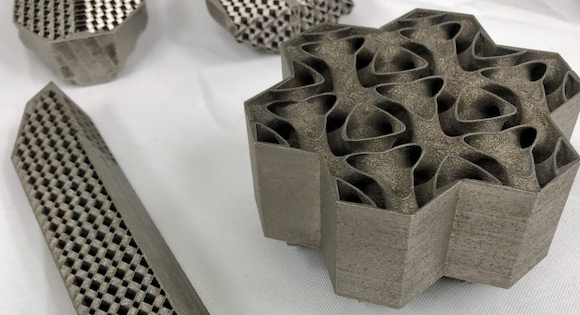

The AIR2WATER device will be a compact, lightweight system that is able to be lifted by four people and produce enough daily water for around 150 troops. The key technologies being used to produce potable water are sorbent materials to absorb the air and an additively manufactured heat exchanger that effectively draws in heat over the sorbent materials to release water.

The team from UC Berkeley, led by Omar Yaghi, Professor of Chemistry, will focus on the development of sorbent materials. To help predict and inform the selection of the best materials, the University of South Alabama, led by Prof Grant Glover, will model the mass transfer and measure the adsorption kinetics, while AI experts from the University of Chicago, led by Prof Laura Gagliardi, will utilise AI-guided molecular screening tools.

GE researchers will oversee these developments and lead the overall system integration, including the AM design of and sorbent integration into the heat exchange, drawing from decades of experience producing heat exchangers for aerospace applications and power generation turbines.

David Moore, Principal Investigator and Technology Manager for Material Physics and Chemistry at GE Research, stated, “By creating a highly portable, compact device that efficiently extracts water from the atmosphere, we can save lives.”