GE opens new $39 million Additive Manufacturing centre in Pittsburgh

April 11, 2016

GE has opened a new manufacturing facility with the aim to drive innovation and the implementation of Additive Manufacturing across the company. The Centre for Additive Technology Advancement (CATA), located near Pittsburgh in Findlay Township, Pennsylvania, USA, will focus on developing and implementing industrial Additive Manufacturing applications from which all GE businesses and customers will benefit.

CATA’s metal AM systems can make parts from cobalt chrome alloys, high temperature alloy Inconel and stainless steel (Image: GE Reports/Chris New)

The new facility represents a $39 million investment over three years and will result in the creation of 50 engineering jobs initially, in disciplines ranging from mechanical and electrical to systems and software engineering. The site is designed as an innovation hub, offering training and development in both design and applications.

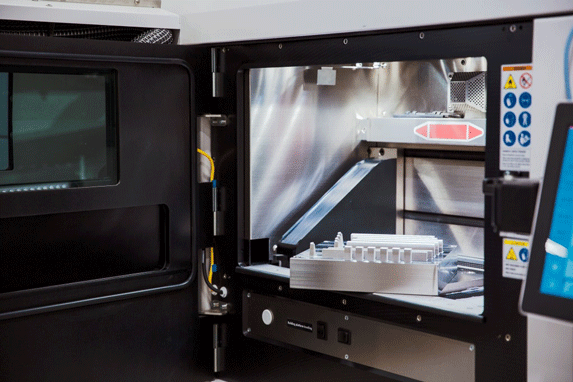

Vacuuming of the DMLM machine to salvage unused metal powder and prevent cross-contamination(Image: GE Reports/Chris New)

“Today’s opening is strong evidence that GE is leading the digital transformation of industry, starting with a hub for the advancement of Additive Manufacturing techniques,” stated GE Chief Productivity Officer Philippe Cochet. “The application of insights from digital connectivity in collaboration with intelligent devices will elevate the skills of our workforce, streamline productivity and enhance product development overall. This represents a new era of manufacturing.”

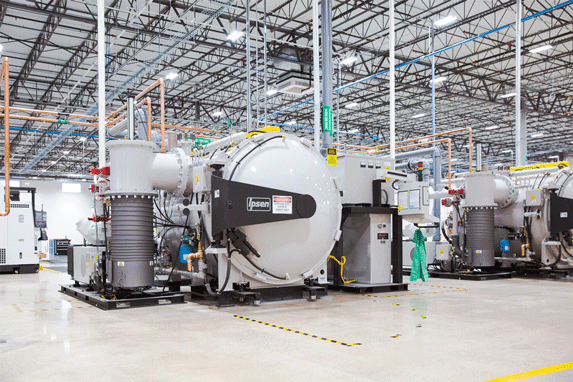

After printing the metal parts are placed inside curing ovens filled with argon or nitrogen (Image: GE Reports/Chris New)

GE is organised around a global exchange of knowledge known as the GE Store, through which each business shares and accesses the same technology, markets, structure and intellect. It is stated that each invention further fuels innovation and application across the company’s industrial sectors.