GB Precision reports on the complexities of machining AM parts for high-precision tooling

January 22, 2018

A component before, during and after machining at GB Precision (Courtesy GB Precision)

Specialist subcontract engineering company, GB Precision, Birmingham, UK, reports that it has been transforming additively manufactured parts into high precision tooling components at its Birmingham facility. The work is reportedly being undertaken for a customer in the high-volume, high-precision packaging sector, and highlights the potential benefits of Additive Manufacturing for tooling component consolidation, improved cooling performance and reduced price/performance of tooling overall.

The design improvement programme is being carried out in a multi-stage approach to ensure that each set of changes is completely tested before moving on to the next. The first stage was to amalgamate three conventionally machined components into a single additively manufactured one, said to have resulted in a 10% cost saving. Once this part was produced, GB Precision had the task of transforming it into a finished, high-accuracy, fine-tolerance component using its machining equipment.

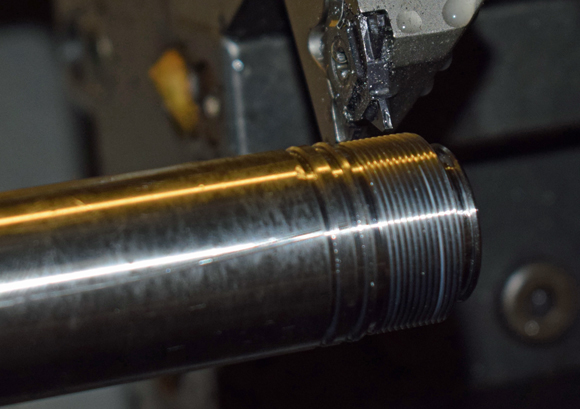

When the AM parts first arrive at GB Precision the surface finish is often rough and granular. One of the first challenges, says GB Precision, is to determine where the machining datum should be. In addition, where conventionally the components would have been machined out of solid bar, making work holding straightforward, the AM parts have more complex shapes, meaning that both the machining process and work holding must be adapted.

An additively manufactured component during machining (Courtesy GB Precision)

In addition, the material itself is said to pose significant machining challenges. GB Precision reported that it has had to experiment with speeds and feeds, depths of cut and differing finishing tools and grinding wheels, as the parameters used for conventionally machined parts do not always apply when machining additively manufactured parts.

Paul Turner, GB Precision Director, explained, “This has really been a ‘learning by doing’ experience. The first batch proved to be very much of an education: the sintered material was incompatible with the tools and roughing process that was used for the conventionally machined parts. However, we have overcome these problems and have developed a process that solves all these issues.”

“There is no doubt in my mind that a combination of laser sintering, conventional machining and surface treatments will provide significant cost, time and material savings and really is the future – and we are determined to be part of that future,” he concluded.