FreeFORM owns world’s largest fleet Desktop Metal machines following addition of sixteen new Binder Jetting systems

September 12, 2023

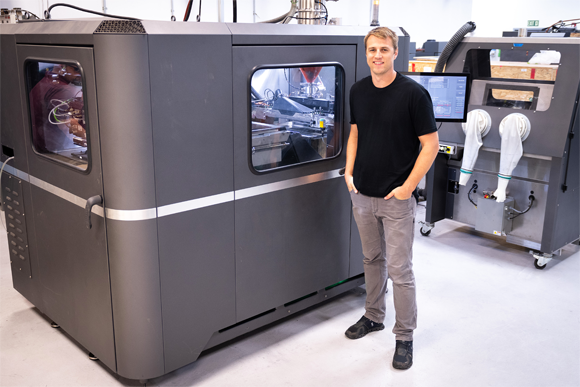

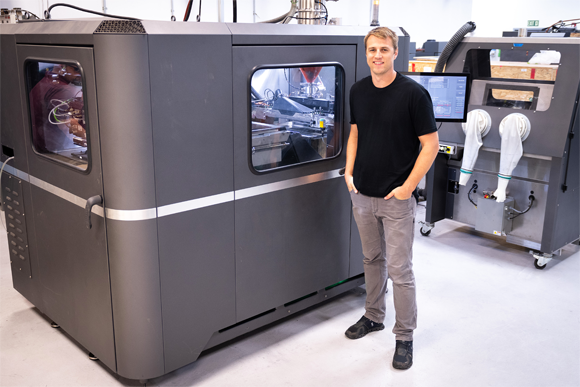

Desktop Metal, Inc, based in Burlington, Massachusetts, USA, has announced the sale of sixteen metal Binder Jetting machines to FreeFORM Technologies, located in St Marys, Pennsylvania, USA. Now including a Production System P-50, along with the shop System, and X-Series models, FreeFORM has a fleet of twenty-five Desktop Metal machines.

“FreeFORM’s investment in metal Binder Jetting demonstrates our continued commitment to employing world-class Additive Manufacturing processes to meet the needs of our customers,” stated Nate Higgins, president of FreeFORM. “This addition of DM printers strengthens our capabilities in this area, allowing us to provide greater cost efficiency and speed to market.”

The company now offers Additive Manufacturing in a wide range of metals, including 17-4PH, 316L, and 420 stainless steels, as well as 4130, 4140 and 4340 low-alloy steels, S7 and M2 tool steels, and infiltrated materials. To-date, FreeFORM has produced over 350,000 parts using Binder Jetting technology for customers in the industrial, defence, medical, robotic, and consumer goods markets.

Founded in 2020, FreeFORM’s primary investor is Ryerson Holding Corporation, a processor and distributor of industrial metals. Ryerson has been a primary investor in FreeFORM since 2022.

“Desktop Metal is delighted to see a startup with deep experience in powder metal and sinter-based technologies pushing the limits of what metal binder jet 3D printing technology can do,” added Ric Fulop, Founder and CEO of Desktop Metal. “FreeFORM is leading the way among our Super Fleet owners, which we define as customers using three or more of our Additive Manufacturing 2.0 systems. Desktop Metal now has hundreds of Super Fleet customers worldwide delivering final production of metal, polymer, and ceramic parts with our binder jet Additive Manufacturing systems. We remain confident that the cost, quality and material flexibility offered by Binder Jetting will continue its momentum in serial AM production.”

Download Metal AM magazine