Fraunhofer IKTS develops complex additively manufactured hardmetal tools

September 22, 2016

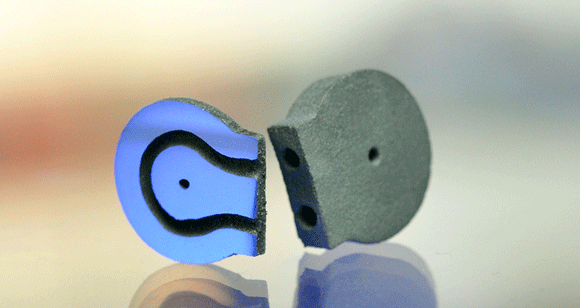

Additive Manufacturing allows the inclusion of integrated cooling channels in complex harmetal tools

Researchers at the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) in Dresden, Germany, have announced the development of complex hardmetal tools via Additive Manufacturing in a quality that is reported to be in no way inferior to conventionally produced high-performance tools.

High mechanical and chemical as well as a high temperature resistance and extreme hardness are required for tools that are used in mechanical and automotive engineering or in the construction and forming industry. Reliable cutting, drilling, pressing and stamping tools made of hardmetals are manufactured by uniaxial or cold isostatic dry pressing, extrusion and injection moulding as well as by green shaping at Fraunhofer IKTS.

IKTS scientists have now succeeded in producing complex hardmetal tools using a binder jetting Additive Manufacturing method. The starting powders or granules are locally wetted with an organic binder by a print head and bound. The challenge with this process was stated to be achieving 100% dense components, which have a perfect microstructure and thus good mechanical properties.

Hardmetals consist of a ceramic hard phase, such as tungsten carbide, and a metallic binder matrix of cobalt, nickel and/or iron. By varying the metallic binder, bending strength, fracture toughness and hardness can be adjusted individually – the lower the amount of binder in the hardmetals, the harder the tool material.

The prototypes manufactured at Fraunhofer IKTS have a binder content of 12% and 17% by weight and show a structure comparable to conventional routes. “Through the use of 3D printed complex green bodies which were subsequently sintered under conventional sintering conditions, we achieved components with a typical hardmetal structure and one hundred percent density. Moreover, it is possible to get a homogeneous cobalt distribution, thus achieving a comparable quality to conventionally produced high-performance cemented carbide-based tools,” stated Johannes Pötschke, Group Leader (Hardmetals and Cermets) at Fraunhofer IKTS.

Fraunhofer IKTS will display its complex prototypes for the first time at World PM2016, October 9 – 13 in Hamburg, Germany, Booth 85.