Fraunhofer IFAM develops Fused Filament Fabrication material for metal part production

October 18, 2017

A stainless steel impeller produced using FFF on a €300 Renkforce RF100 AM system (Courtesy Fraunhofer IFAM)

Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM), Dresden, Germany, has introduced a process which uses Fused Filament Fabrication (FFF) to additively manufacture metal parts. The process is said to allow free formed metal part production from a wide variety of materials with low investment costs.

While FFF is an established process, it has previously been used primarily for the manufacture of polymer parts. The IFAM method uses a plastic filament containing metal powders at up to 55% volume loading. The process involves manufacturing the part using a commercially available standard FFF printer, followed by debinding and sintering to result in a metal part.

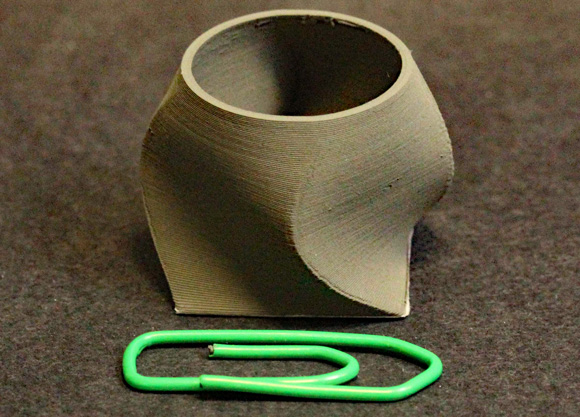

316L stainless steel demonstrator part made by FFF (Courtesy Fraunhofer IFAM)

So far, the process has mainly been used to produce components in 316L stainless steel, but is reportedly suitable for all sinterable metals, including copper, tungsten, titanium and precious metals, as well as ceramics. It is said to also be possible to produce multi-material parts.

The process is reportedly undergoing development for commercialisation, with the aim of producing cost-effective components to industrial standards. According to Fraunhofer, FFF AM machines cost only a fraction of the price of powder bed AM machines and allow for the production of free-formed metal parts with >97% density. In addition, FFF uses MIM-cut metal powders, which are typically cheaper than powders for powder bed Additive Manufacturing.