Fraunhofer demonstrates vibration-eliminating support structures for post-processing of metal AM parts

July 24, 2018

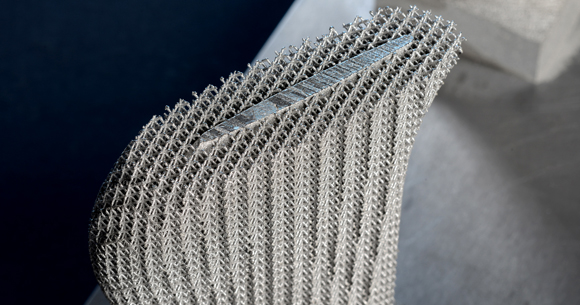

Fraunhofer IPT and ILT have developed a support structure design which is said to eliminate vibration during post-processing (Courtesy Fraunhofer IPT)

The Fraunhofer Institutes for Production Technology (IPT) and Laser Technology (ILT), Aachen, Germany, have developed a new design for support structures which is said to eliminate part vibration during post-processing operations such as milling or grinding. Milling operations conducted on thin-walled parts in particular often cause vibrations which can negatively impact both part accuracy and machining time.

As a rule, metallic components manufactured using Powder Bed Fusion (PBF) processes are designed with a larger-than-usual oversize to allow for functional surfaces to be finished in milling operations, since this is the only way of ensuring that all of the surface tolerances and quality requirements can be met. Thin-walled parts are particularly prone to vibration in the course of the machining and material removal operations, and this can result in poor surface quality or even render the components unusable.

Support structures for the reduction of vibration during milling (Courtesy Fraunhofer IPT)

Fraunhofer IPT and ILT’s new support structures are said to increase the stiffness of susceptible areas of AM parts and thereby reduce vibrations during post-processing. They can also be removed with relatively little effort in the course of the surface finishing operation. Parts stabilised in this way can reportedly be manufactured in higher quality in less time, and with lower level of tool wear.