ExOne launches online cost estimation tool

January 20, 2021

The ExOne Company, North Huntingdon, Pennsylvania, USA, has launched a new online estimation tool for companies considering moving production of metal parts to high-speed binder jet (BJT) Additive Manufacturing.

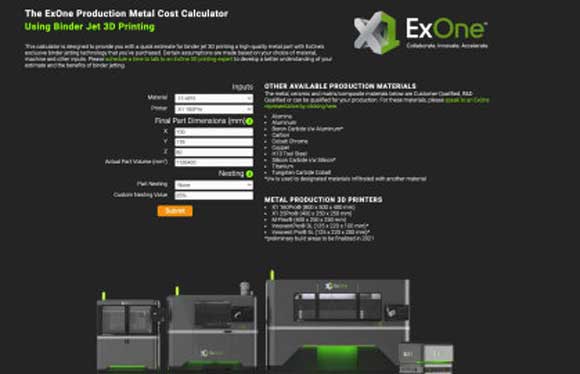

The ExOne Production Metal Cost Calculator is designed to provide manufacturers with a per-part estimate for Binder Jetting a precision metal part so they can quickly compare the technology to other forms of traditional and Additive Manufacturing.

The company explains that the new tool requires a few easy inputs – material, machine, part dimensions and volume – and is based on the purchase of any one of its four Pro series AM machines.

“As customers compare new Binder Jetting options in the marketplace, we wanted to provide greater transparency into the affordable costs of Binder Jetting with ExOne technology,” stated John Hartner, ExOne’s CEO. “Our new estimating tool takes a comprehensive range of costs into account, such as initial capital investment, throughput speeds, material, binder, replacement printheads, and more. Our team is confident that our high-speed systems offer the best value in terms of build area, throughput, consumable costs, material flexibility, and experience.”

ExOne’s production-ready lineup includes:

- X1 25Pro® large metal AM machine, launched in 2019. It offers a maximum build rate of 3,600 cc/hr

- X1 160Pro™ extra-large metal AM machine with a maximum build speed of 10,000 cc/hr, which is in production at ExOne’s German facility and shipping to customers soon.

- InnoventPro™, which comes to market in late 2021 with a 3- or 5-litre build volume and is a faster version of the Innovent+®.

ExOne’s complete family of Pro series AM machines are capable of Additively Manufacturing more than twenty materials, including eleven single-alloy metals, five composite metals and four ceramics. Usable metals include 17-4PH, 316L, 304L, cobalt chrome, copper, H13 tool steel, Inconel 718, Inconel 625, M2 tool steel, titanium, and tungsten heavy alloy.

Aluminium, which is already qualified for R&D use on ExOne AM machines, has been fast-tracked for ExOne’s highest third-party qualification status, explains the company, which indicates general market readiness. ExOne’s first aluminium alloys are expected to receive this status upgrade during 2021.