ExOne adds new stainless steels to Quick Ship metal Additive Manufacturing service

June 20, 2020

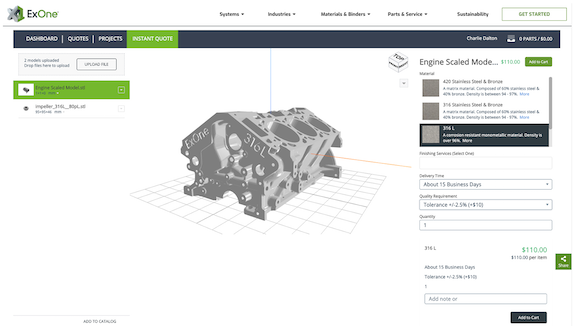

The ExOne Company, North Huntingdon, Pennsylvania, USA, has launched its updated Quick Ship metal Binder Jetting (BJT) Additive Manufacturing services, featuring a new digital quoting tool and materials. The updated ExOne Quick Ship adds the popular stainless steels 316L and 17-4PH to the list of materials offered through instant quoting.

A new Quick Ship online dashboard will allow customers to upload a qualifying digital design file for an instant quote and purchase, as well as create an account to track projects. More than thirty file types are accepted, including STL and STP files. Using Quick Ship, 316L and 17-4PH parts will be available with delivery times of 10–15 business days, depending on number of units requested, part size and other requirements.

“After two years of supplying thousands of 316L and 17-4PH parts to select industrial customers, our updated Quick Ship services will now allow any customer to easily acquire and evaluate affordable single-alloy parts 3D printed with Binder Jetting,” stated John Hartner, ExOne CEO.

Quick Ship parts will be additively manufactured at ExOne’s metal production facility outside Pittsburgh, Pennsylvania, which has been Binder Jetting metal parts for more than two decades. It’s home to a fleet of more than two dozen metal AM machines producing parts for prototype, low-volume, and serial production projects.

In development since 1996, ExOne’s BJT machines are capable of producing parts in more than twenty metals, ceramics and composite materials. Quick Ship parts in 316L and 17-4PH will be manufactured on ExOne’s Innovent+ and X1 25Pro metal BJT machines.

Both machines feature ExOne’s exclusive Triple ACT system, described as an advanced compaction technology that delivers industry-leading density and repeatability in metal Binder Jetting. ExOne machines with Triple ACT are capable of delivering sintered dimensional accuracy of +/- 2.5% on a first BJT run, with better results possible after additional sintering optimisation.

“The launch of Quick Ship services for single-alloy metals represents a key step forward in our development of metal Binder Jetting, and one that signifies our continued confidence in this technology,” commented Rick Lucas, ExOne’s Chief Technology Officer and VP of New Markets. “We also have plans to expand the number of material offerings and size of printable parts in our Quick Ship services by year-end.”

ExOne will also continue to offer its popular 316 and 420 materials infiltrated with bronze on its M-Flex and R2 metal AM models, which have been in operation since 2013 and 2003, respectively. Infiltrated parts, which offer a variety of functionality and finish benefits, are typically shipped within ten business days.