EWI adopts Granta MI software for better Additive Manufacturing

January 28, 2019

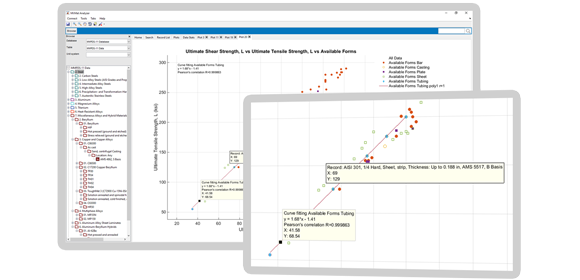

Granta’s MI software is used for enterprise materials information management (Courtesy Granta Design)

Granta Design, Cambridge, UK, will provide its Granta MI software to EWI, a provider of advanced engineering services headquartered in Columbus, Ohio, USA. EWI will reportedly use the software to better coordinate its Additive Manufacturing work across multiple AM platforms. The software system is currently being deployed within the company.

Granta MI is used for enterprise materials information management. Serving as a single source for all of an organisation’s materials data, it saves time, cuts costs and eliminates risk. Apps, tools to capture and reuse knowledge, and support for CAD, CAE, and PLM all help to drive material innovation, empower design, and solve materials-related business problems.

EWI’s comprehensive engineering services aim to help companies identify, develop and implement the best options for their specific applications. Defining a strategy to capture and characterise material information across different AM platforms is currently a challenge, however. Every AM machine monitors different metrics, and exports data differently.

EWI hopes to meet this challenge by defining the most effective way to record the data, and then automating and controlling the input process through Granta MI. If further metrics are identified as essential to the qualification of a part, the flexibility of Granta MI and EWI’s importing strategy will allow the enterprise to go back and pull in that information with ease.

“We know AM has the potential to be a great tool to meet today’s industry needs, but we also recognise that hesitation to adopt such technology may be due to lack of understanding of the entire process from start to finish,” commented Brendan Lewis, EWI Project Engineer and Team Lead for Granta MI implementation.

“GRANTA MI will to allow us to capture large amounts of data from all pieces of the AM puzzle and present it in a way that makes sense to the prospective industry adopters. This data capture will allow us to make valuable correlations that can be used to generate data driven standards across the industry, and streamline the development of AM parts internally.”

“We are very excited to be working with the Granta team on this project,” he added. “Their intuitive Granta MI interface, diverse portfolio of industry impact, along with a clear understanding of Additive Manufacturing has really allowed us to hit the ground running.”

Through the ASTM AM Center of Excellence (CoE), EWI is also working on a variety of programmes designed to generate data for standards development. This data will be used to help companies understand the properties of AM parts, and improve process parameter development. Granta MI is said to support this by capturing a wide variety of data from the full AM value chain – from feedstock characterisation to final material property data. This tracked data includes build information, post-process information, non-destructive testing and mechanical testing.