Essentium and Nuburu partner to develop blue laser AM machine

May 4, 2022

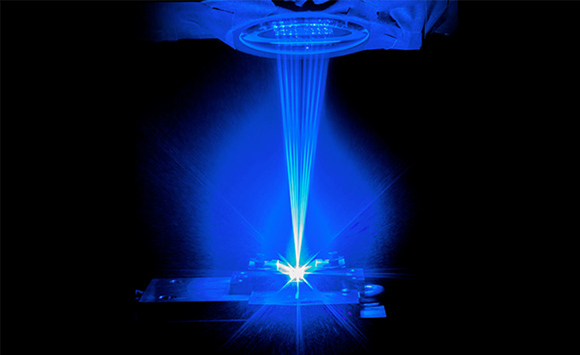

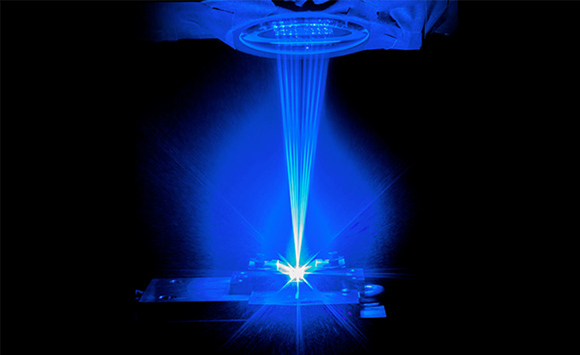

Blue laser solutions provider Nuburu, Centennial, Colorado, USA, has partnered with Essentium, Inc, Austin, Texas, to develop a blue laser-based metal Additive Manufacturing platform. The resulting machine is hoped to enable manufacturers to create production-grade metal parts with high resolution and fast throughput.

As a part of the contract, Nuburu will also license its core Additive Manufacturing application patents, based on its foundational patent ‘Methods and systems for welding copper using blue laser’.

Nuburu’s blue laser is said to be well suited to materials processing applications within AM. Critical materials such as copper, stainless steel, and aluminium reflect much of the infrared wavelengths transmitted by traditional industrial lasers, which leads to lower build speed and quality. Nuburu’s blue laser technology is said to enables Additive Manufacturing with 10x the build speed and the ability to built with a very high metal density without any post processes.

Under the multi-year, multi-million-dollar agreement, Essentium may integrate Nuburu’s proprietary blue laser technology with its High Speed Extrusion (HSETM) Additive Manufacturing technology for product development in the first phase, and manufacturing in the second phase. The new AM platform is designed to deliver breakthrough throughput for extremely high part quality and broad-scale use in major industrial markets, including automotive, aerospace, and defence.

“We are excited to work closely with the Essentium team and combine the powers of our existing technologies to develop and manufacture a new transformative platform for additive manufacturing,” stated Mark Zediker PhD, co-founder, CEO, and president at Nuburu. “Our high power, high brightness blue laser technology, along with our 3D printing IP will help Essentium build a powerful metal 3D printer with a wide range of applications.”

Elisa Teipel, PhD, Chief Development Officer and co-founder of Essentium, added, “Nuburu is the leader in blue laser technology, and their expertise will help enable gains in speed and power within our new platform. We are looking forward to working with their team and leveraging their technology, enabling Essentium to commercialise a new metal 3D printing platform.”