Equispheres introduces NExP-1 non-explosible aluminium feedstock

November 16, 2022

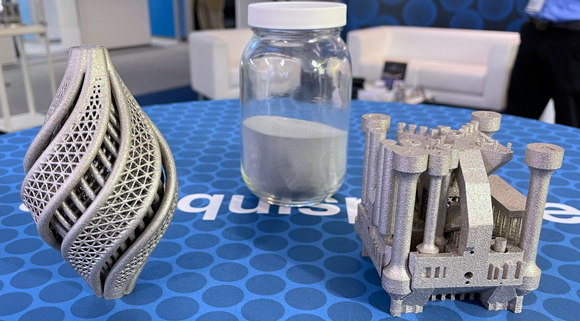

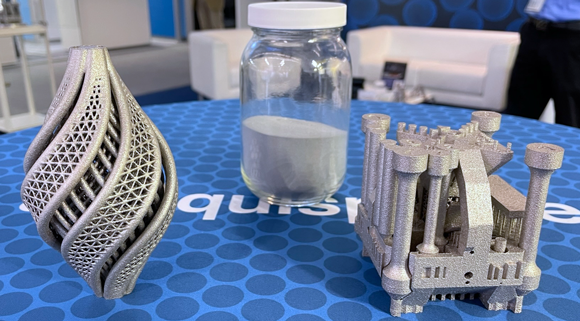

Equispheres, Inc, Ottawa, Ontario, Canada, has announced its development of a non-explosible aluminium alloy feedstock for Additive Manufacturing that reduces the hazards associated with the day-to-day handling of metal powders. Known as NExP-1, the material is designed for the production of additively manufactured aluminium parts.

The company explains that NExP-1 maintains the ability to produce high-quality builds at high throughput rates, but, unlike other metal powders for Additive Manufacturing, it is dust-free and characterised as non-explosible as per ASTM E1226, Standard Test Method for Explosibility of Dust Clouds. The material is also non-combustible as per the UN Manual of Tests and Criteria, Part 3, Subsection 33.2.1. for flammable solids.

“We have achieved these key safety properties without altering the quality of our material nor the chemical composition. In printing, this material performs just as well as our other aluminium powders, but it has the added benefit of being non-explosible and non-combustible,” stated Evan Butler-Jones, vice president – Product & Strategy for Equispheres.

“It would almost be inaccurate to even call this a powder,” Butler-Jones continued. “It is almost totally free of dust; it flows like water and it is easy to clean off of equipment surfaces. It is a completely unique printing media for production Additive Manufacturing.”

The NExP-1 material is currently available in AlSi10Mg and the company has developed recommended parameters for additively manufacturing the new material, targeting several end-use applications.

Kevin Nicholds, CEO of Equispheres, commented, “We are applying our technology to empower innovation in Additive Manufacturing. We anticipate this new safer aluminium material will be embraced by companies using AM in a production setting. This new breakthrough is a result of our ongoing efforts to make 3D printing more accessible and competitive with other manufacturing methods.”

Equispheres has a core team of metallurgists actively engaged in R&D and continues to develop processes and products to advance the technology of AM. The company’s Performance and Precision lines of aluminium powder demonstrate marked improvement in build speed and part quality, resulting in lower per-part costs. NExP-1, an addition to Equispheres’ Production product line relies on a technological breakthrough to address the handling properties of AM powders.

Equispheres is exhibiting at Formnext 2022 and is located in hall 11, B31.