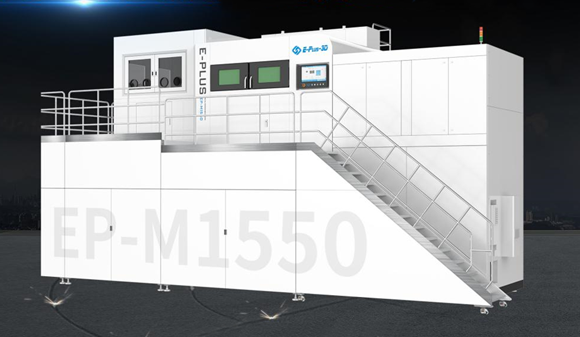

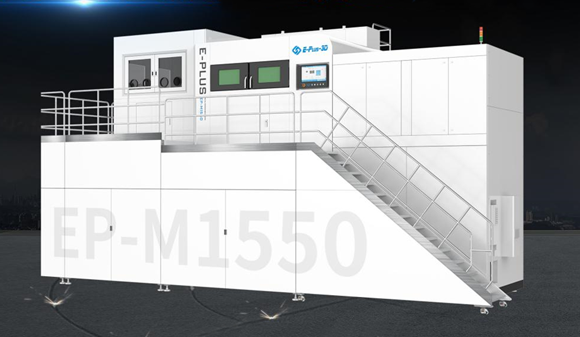

Eplus3D launches sixteen-laser EP-M1550 Additive Manufacturing machine with twenty-five laser option

September 15, 2023

The EP-M1550 Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing machine incorporates a novel four-by-four laser matrix and sixteen galvanometers. This allows the sixteen lasers to operate synchronously, ensuring a high build rate of up to 650 cm³/h. If the machine is upgraded to twenty-five lasers, the optics system includes a five-by-five laser matrix and twenty-five galvanometers.

Further options include either 500 W or 700 W fibre lasers, providing the capability to process a wide range of materials such as titanium alloys, aluminium alloys, stainless steels, and tool steels. This offers the same number of material options as Eplus3D’s smaller frame systems. The EP-M1550 can manufacture at a layer thickness of between 20 – 120 µm and is reported to be well suited to manufacturing large-size, high-precision, and high-performance parts for the aerospace and other demanding industries.

“We have solved the technical challenges and bottlenecks associated with ultra-large metal LPBF machines and approached the leading level in the industry in terms of advancement and stability of our systems,” stated shared Mary Li, General Manager International Division, Eplus3D. “Delivering nearly twenty ultra-large machines with printing size 1250 x 1250 x 1000 mm or bigger to our customers where they are producing parts in a production environment. Eplus3D will continue to provide more reliable and applicable production-level AM systems and solutions to help more customers from the industry.”

Download Metal AM magazine