A first look at the EOS M 300, set for September launch

July 23, 2018

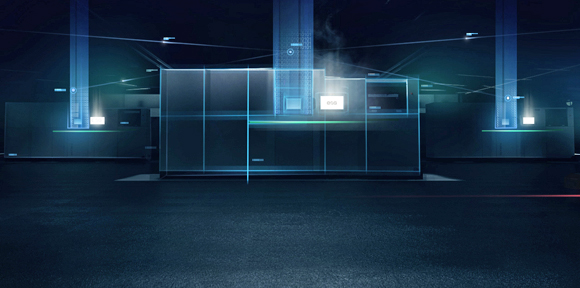

EOS offered visitors a first look at its upcoming EOS M 300 system (Courtesy EOS)

At the exclusive EOS Technology Days at its headquarters in Krailling, Germany, July 17-18, 2018, EOS unveiled to a select number of visitors the first details of its upcoming EOS M 300 metal Additive Manufacturing series. The EOS M 300 will have its official debut during the International Manufacturing Technology Show (IMTS) in Chicago, Illinois, USA, this September, and is expected to begin shipping in 2019. Metal Additive Manufacturing magazine attended the event for a first look at the machine and its capabilities.

During the event, Dr Tim Rüttermann, Director of Product Management at EOS, explained that the EOS M 300 is “a response to customer demand for something close to the well-established EOS M 290, but scalable for a high volume production factory setting.” The system will reportedly offer a productivity increase of 4-10 times that offered by the EOS M 290, and employs four lasers. The new design offers full field overlap with four scanners, meaning that lasers can reach all spots on the build plate and full flexibility is possible with regards to build orientation.

In order to enhance part reliability and quality, Karsten Behrend, EOS Product Management, explained that the new system features a gas flow optimised build chamber. Poor gas flow can result in builds which lack the proper mechanical properties, are unacceptably porous, or show a general lack of fusion. The new gas flow design is said to reduce the risk of condensate and ensure a strong flow of gas through the top and bottom of the build chamber, efficiently clearing smoke and debris generated during processing.

Also key to the reliability of the system is the incorporation of a permanent filter system – eliminating the need to open the machine up periodically for filter changes, highlights Sebastian Becker, EOS Product Management. The new recirculating filter system offers automated cleaning, with residue collected in a bin beneath the build chamber.

Tim Rüttermann (left) and Thomas Weitlaner (right) presented during the Technology Days event at EOS headquarters (Courtesy EOS)

As EOS turns its focus to series production and the development of solutions for the digital factory, key areas of development across its product range are increased productivity; reliable and repeatable part quality; production flexibility and automation; and efficient process control. The new EOS M 300 has been developed for automation and integration in current and future factories. “‘Our mission is to make EOS the most attractive platform and ecosystem to develop and industrialise applications, materials and processes,” stated Rüttermann.

For better production flexibility and automation, the EOS M 300 offers different solutions for dosing, unpacking, recoating and monitoring depending on the needs of the user, including powder contact-free solutions for health and safety, and is fully compatible with the current EOS powder management portfolio. It will be offered with the company’s existing EOSPRINT 2, EOSTATE and upcoming EOSCONNECT software platforms, for build preparation, production and monitoring respectively.

The company also stated that the system will be compatible with the EOS Shared Modules concept, in which manual or automated peripheral modules and transport logistics supply several EOS metal AM systems, meaning that all set-up, unpacking, transportation and sieving actions will be carried out independent of, and parallel to, the AM build process. The first implemented models of the Shared Modules system are currently in operation at some major partners, but a release date for its commercial launch has not yet been made available.

EOS currently has an installed base of more than 3,000 systems around the world. While it took roughly 20 years to bring the first 1,000 systems into the market, EOS has installed the latest 1,000 of its AM systems at customer facilities just over the past two to three years, according to Thomas Weitlaner, Director Business Development. These numbers emphasize how fast industry and market are growing. The company has a network of global sales and service offices in fifteen countries, six innovation centres and more than 250 service specialists. “EOS sees serial production with AM coming, and is ready to support its customers,” Weitlaner stated.