EOS and Siemens strengthen partnership for Additive Manufacturing

September 11, 2018

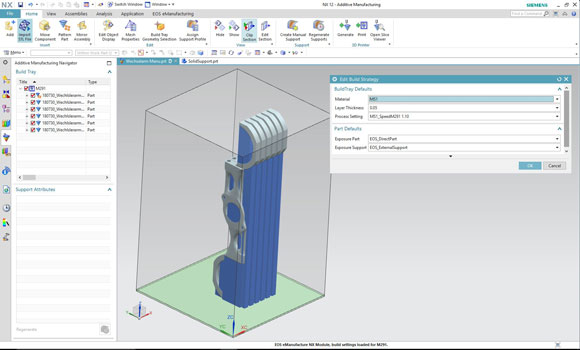

The EOSPRINT driver for Siemens NX (Courtesy EOS)

EOS, based in Krailling, Germany, has strengthened its partnership with Siemens AG, Munich, Germany, for the acceleration of Additive Manufacturing technology development and its application. In a statement highlighting the companies’ ongoing cooperation, EOS revealed that its new EOS M 300 series of metal Additive Manufacturing system, previewed by Metal AM in July 2018 and officially launched this month at IMTS 2018, uses automation and drive technology from Siemens’ Totally Integrated Automation (TIA) portfolio.

Alfons Eiterer, Head of System Engineering, EOS, commented, “EOS puts a strong focus on high quality and reliability in its new developments, while at the same time ensuring dynamical and technological progress. This is the reason we chose Siemens control technology for our new EOS M 300 series. With Siemens we can rely on proven technical components and are well prepared to handle future requirements.”

In addition to using Siemens components in its latest system, EOS’s EOSPRINT 2 CAM tool is now included in Siemens’ NX 12 AM module, a software solution for process steps from design, to topology optimisation and process simulation, to print preparation. The company stated that the functions of EOSPRINT 2 have been seamlessly integrated into Siemens’ NX Fixed Plane (Powder Bed) AM software module to support the use of Siemens’ module with EOS systems.

“A fast industrialisation of Additive Manufacturing can only be unleashed by a close cooperation of experts from a software, automation and drive system angle with industrial 3D printing experts, as is the case with Siemens and EOS,” stated Dr Karsten Heuser, VP of Additive Manufacturing at Siemens AG. “We are therefore proud to move with EOS into the next level of industrialisation, which will help transforming AM further from the prototyping phase into industrial serial production.”